In the global automotive aftermarket, the differences between commercial vehicle and passenger vehicle brake discs are significant. However, high-performance, wear-resistant, and anti-rust coated brake discs that are compatible with 99% of vehicle models are becoming the key solution in the export market. This article delves into the core differences in the brake system requirements of these two types of vehicles and reveals why high compatibility is not only a technical advantage but also the underlying logic for global market expansion.

Let's start with real - world scenarios. For commercial vehicles, frequent brake disc replacements due to premature wear are a common headache. In some cases, commercial vehicles need to replace brake discs every 30,000 - 40,000 kilometers. On the other hand, passenger vehicles often suffer from brake noise and reduced braking performance when the brake discs are not well - matched. These issues not only increase maintenance costs but also pose safety risks, which resonate with many automotive industry professionals.

Passenger vehicles and commercial vehicles have different requirements in terms of load capacity, operating conditions, heat load, and installation space. Commercial vehicles usually carry heavy loads, operate in more complex road conditions, and generate higher heat during braking. They require brake discs with high strength and heat dissipation. In contrast, passenger vehicles focus more on quiet operation and compact design. A single - design brake disc cannot meet the diverse needs of the global market. According to industry reports, over 70% of brake disc - related complaints are due to the mismatch between the brake disc and the vehicle type.

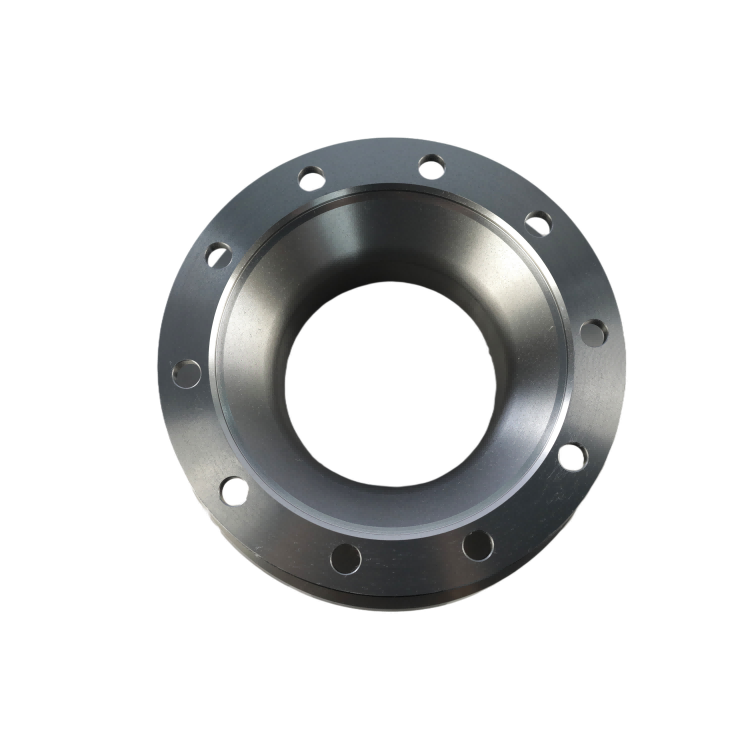

To address these challenges, several key technical breakthroughs have been made. In terms of materials, the choice between gray iron (GG20) and high - carbon steel is crucial. Gray iron provides good heat dissipation, while high - carbon steel offers high strength. Precision machining ensures the dynamic balance of the brake disc, reducing vibration and noise during braking. Advanced anti - rust coating technology not only protects the brake disc from corrosion but also enhances its wear resistance. Multiple layers of anti - rust coating can extend the service life of the brake disc by up to 50% compared to traditional brake discs.

Certifications play a vital role in building trust in the export market. IATF TS16949 certification ensures that the manufacturing process meets the highest quality standards in the automotive industry. The R90 E - mark certification is a mandatory requirement for brake products sold in the European market, indicating compliance with safety and performance regulations. The VCA COP quality audit further verifies the product's quality and reliability. Products that pass these certifications are more likely to gain the trust of international customers.

The high - compatibility brake discs offer a comprehensive customer value proposition. With a 99% model coverage, customers can reduce the complexity of procurement. A two - year warranty and an 80,000 - kilometer performance guarantee provide peace of mind. This forms a complete experience chain of "worry - free selection, confident use, and reliable after - sales service", helping customers reduce procurement risks and improve operational efficiency.

In conclusion, high - compatibility brake discs are the future of the global brake disc export market. By understanding the differences between commercial and passenger vehicle brake discs and leveraging advanced technologies and certifications, manufacturers can provide better products and services to global customers. If you are interested in learning more about our high - compatibility brake discs, such as obtaining our technical whitepaper or consulting for a customized solution, please click here.

.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)