As a professional mechanic or fleet manager, you know that every brake job matters—not just for performance, but for safety. Yet studies show that up to 42% of brake-related incidents in commercial fleets stem from improper installation, not faulty parts.

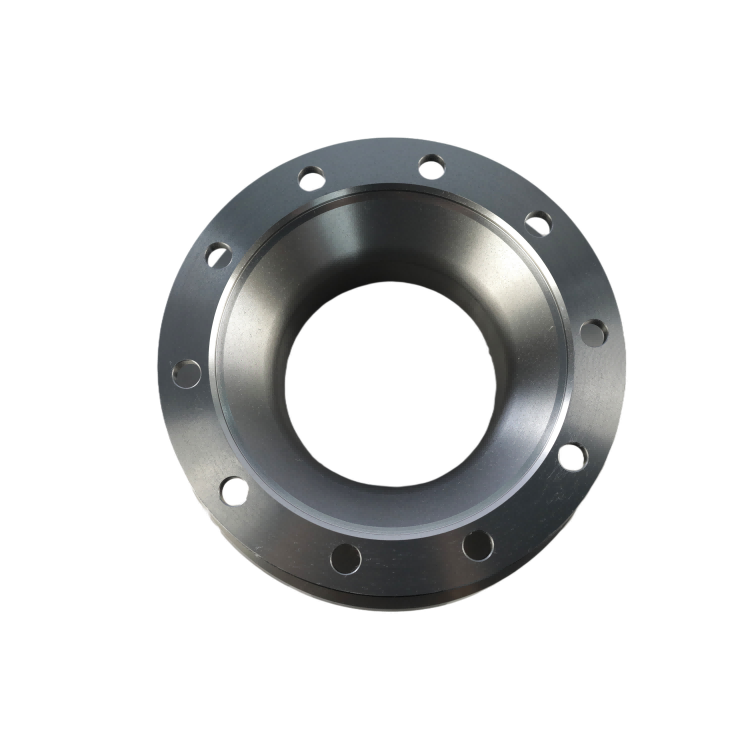

Many technicians skip checking the alignment between the hub and disc’s positioning holes—a step that seems minor but can cause uneven wear, vibration, and even brake fade under load. A recent case study by the European Fleet Safety Association found that 67% of premature disc failures were linked to misaligned mounting surfaces. Our discs feature high-precision positioning holes (±0.05mm tolerance) and are manufactured under IATF TS16949 standards—ensuring repeatable fitment across thousands of installations.

Using a standard wrench instead of a torque wrench might seem efficient—but it leads to inconsistent clamping force. That’s why we recommend using a calibrated torque wrench set at 100–110 Nm (per OEM specs). Also, always measure flatness with a dial indicator before installing. A 0.03mm deviation in surface runout can lead to pedal pulsation and reduced braking efficiency over time. Our machining process includes precision grinding for consistent thickness and flatness—no compromises.

After installation, don’t rush off to the next job. Test the rotor rotation manually—if there’s any drag or resistance, recheck your caliper alignment and pad seating. In one real-world example, a long-haul trucking company saw a 30% drop in brake-related downtime after implementing our standardized checklist. That’s not magic—it’s consistency.

If you're tired of troubleshooting brake noise, vibrations, or unexpected failures, it’s time to shift focus from "fixing what breaks" to "installing what lasts."

Explore our full range of precision-engineered brake discs designed for durability, safety, and ease of installation—backed by ISO-certified manufacturing and proven field results.

Get the Pro-Level Brake Disc Kit TodayHave you experienced brake issues due to poor installation? Share your story below—we read every comment and use feedback to improve our guides and products.