In the maintenance and repair of commercial vehicle brake systems, the accurate installation of brake discs plays a pivotal role in ensuring operational safety and longevity. A recurrent issue encountered in workshops and fleets worldwide involves inaccuracies rooted in the positioning of locating holes and the associated machining processes. This article delves into these technical pitfalls—underscoring how locating hole precision and turning operations directly affect braking safety and overall performance.

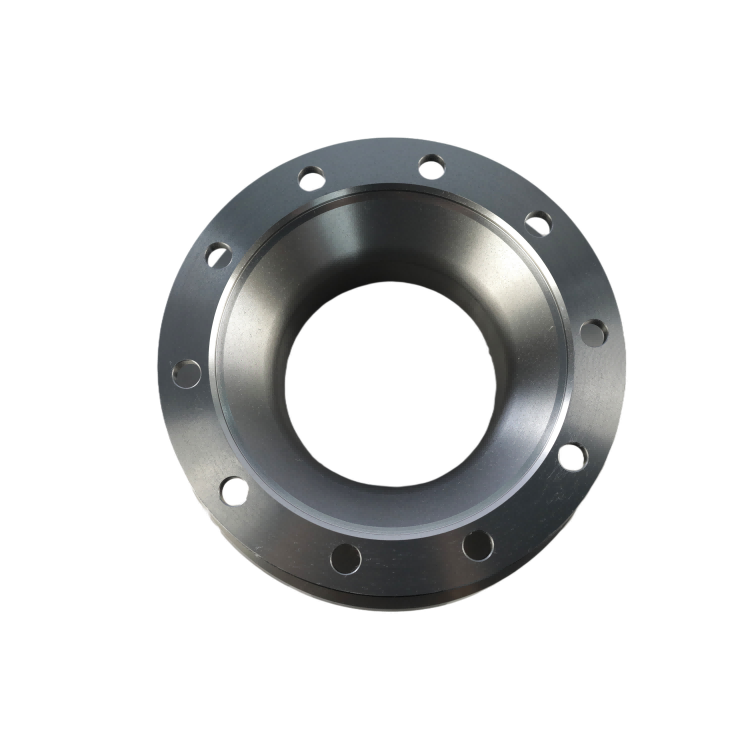

The locating holes on a brake disc serve as the interface, aligning the rotor firmly to the hub. Even minor deviations in the diameter, roundness, or axial positioning of these holes can lead to uneven contact patterns, resulting in vibration, noise, and premature component wear. Industry studies indicate that a locating hole tolerance deviation as small as 0.05 mm can increase runout by 20%, significantly compromising braking stability.

Maintaining high precision in these holes is critical not only for fitment but for preserving the geometric integrity of the disc during and after the vehicle's operational cycle.

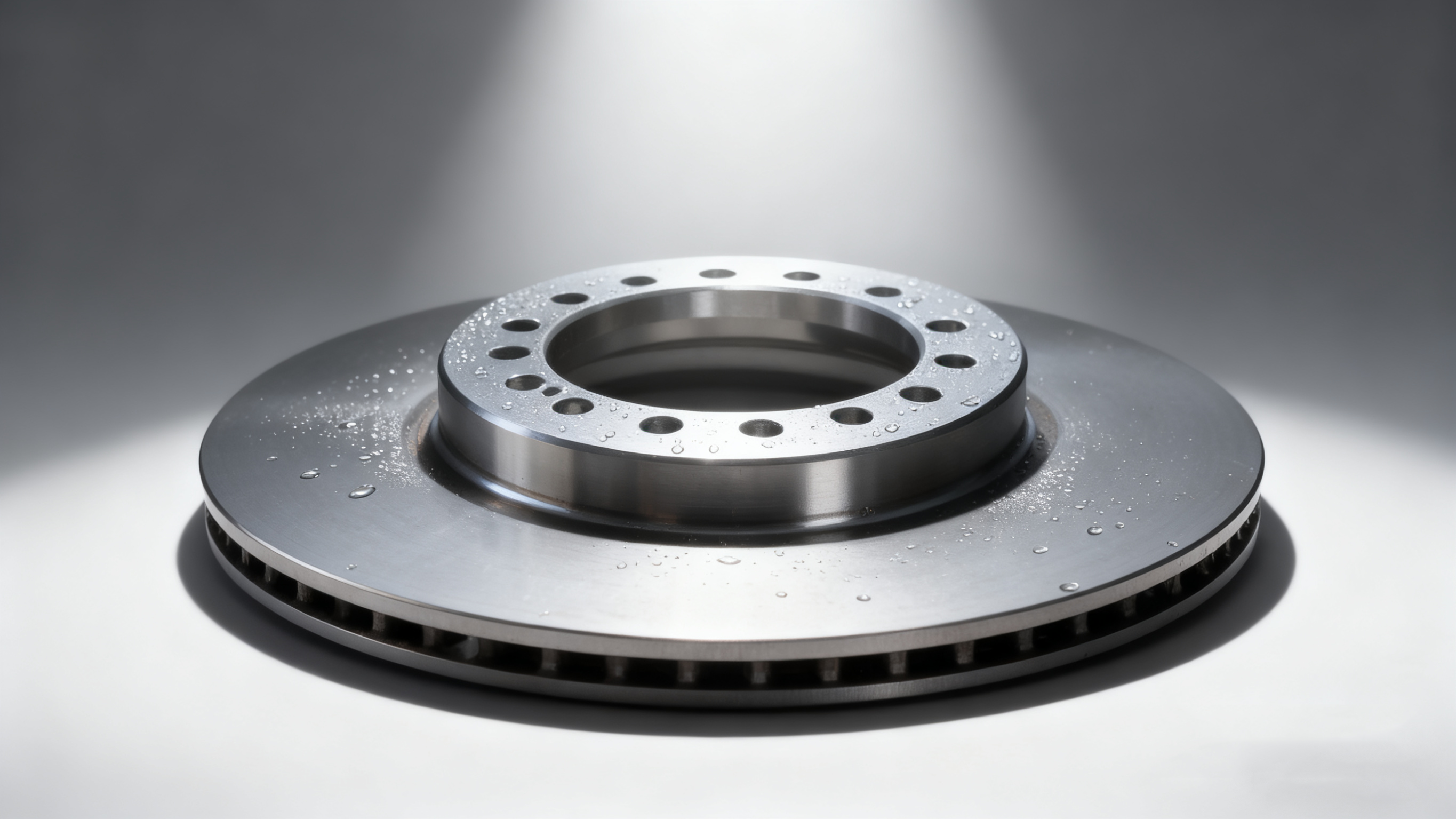

Turning processes—encompassing both turning and grinding of brake disc surfaces—ensure that the rotor exhibits uniform thickness and flatness, directly influencing braking force distribution. Without stringent control over turning parameters, distortions, thermal stresses, and uneven wear emerge, severely undermining safety. Research confirms that maintaining surface flatness within 0.02 mm tolerance reduces vibration occurrences by nearly 35% in commercial vehicles.

Adopting precision CNC machining combined with controlled grinding cycles has become the industry best practice for achieving consistent surface quality and thickness uniformity.

To mitigate risks linked to improper installation, workshops and fleet managers should adhere to a standardized procedure that encompasses:

Implementing these steps significantly reduces the incidence of noise complaints, uneven pad wear, and potential brake failure.

Graphical comparisons and real-world examples underscore the cost of deviation:

Such disparities highlight how precise hole placement and machining translate into tangible safety and maintenance benefits.

Selecting a high-quality brake disc with certified tolerances and validated manufacturing processes is fundamental for ensuring system reliability. Products boasting ISO 9001 and TS16949 certifications, along with validation against international standards such as SAE J431, are proven performers.

Additionally, comprehensive after-sale policies covering installation assistance, wear analysis, and warranty services empower fleet operators to maintain peak brake performance with confidence.