Brake disc installation errors are a common headache in the commercial vehicle maintenance industry. These mistakes can lead to a range of problems, from minor annoyances like strange noises and vibrations to serious safety hazards such as brake failure. In this section, we'll explore some of the most common installation mistakes through real - life cases.

One prevalent error is the misalignment of the positioning holes. For example, in a large logistics company's fleet maintenance, mechanics failed to align the brake disc's positioning holes accurately with the hub. This misalignment led to uneven stress distribution during braking, causing the brake pads to wear unevenly. As a result, within just 3,000 kilometers, the brake pads needed to be replaced, and the braking performance significantly decreased.

Another common issue is the use of brake discs with rough machining. A small repair shop once installed brake discs that were not properly turned and ground. The uneven surface of the brake discs caused vibrations when braking, making the drivers feel unsafe. After investigation, it was found that the surface roughness of these brake discs exceeded the standard by 50%, directly affecting the braking stability.

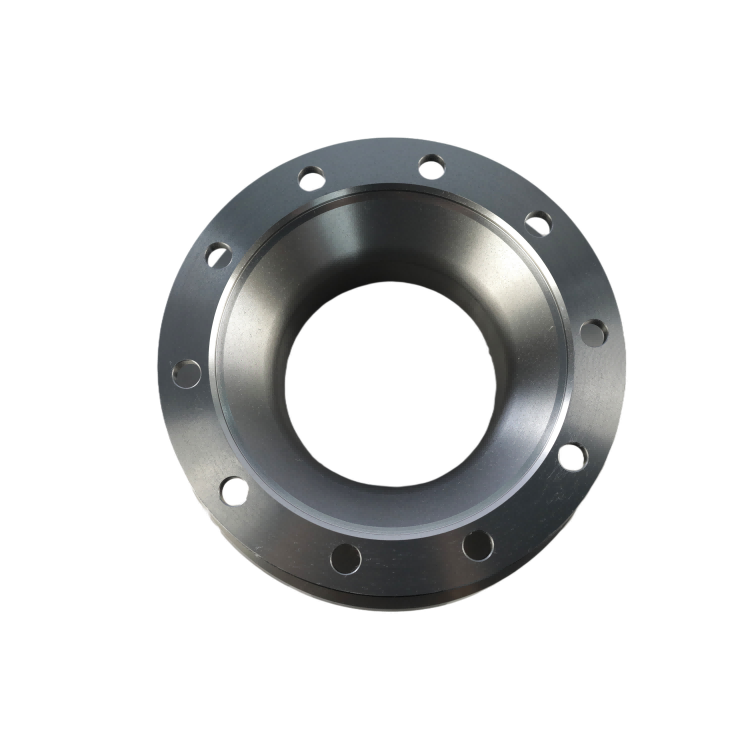

The design of precise positioning holes is the cornerstone of brake disc installation. These holes are designed based on strict geometric and mechanical principles. The positioning holes are precisely calculated to ensure that the brake disc is perfectly centered on the hub, allowing for uniform force distribution during braking. For instance, our company's brake discs have positioning holes with an accuracy tolerance of within ±0.05mm, which is far superior to the industry average of ±0.1mm.

Turning and grinding processes play a crucial role in ensuring the consistency of the brake disc surface. During the turning process, the cutting tool precisely removes excess material to achieve the desired thickness and surface finish. Grinding further refines the surface, reducing roughness and ensuring flatness. Our advanced turning and grinding equipment can maintain a thickness consistency within ±0.03mm across the entire brake disc surface, effectively preventing vibrations and uneven wear.

Proper installation is key to maximizing the performance and lifespan of brake discs. Here are the step - by - step installation guidelines:

Use high - quality torque wrenches, socket wrenches, and cleaning tools. Ensure that the tools are calibrated regularly to guarantee accurate torque application.

Thoroughly clean the hub and the brake disc mounting surface to remove any dirt, rust, or debris. A clean surface ensures a tight fit and prevents uneven stress.

Align the positioning holes of the brake disc with those on the hub carefully. Use a guiding pin if necessary to ensure accurate alignment.

Tighten the bolts in a cross - pattern to ensure even pressure distribution. The recommended torque for most commercial vehicle brake disc bolts is between 80 - 120 Nm. Do not overtighten or undertighten the bolts, as this can lead to serious problems.

To better illustrate the difference between correct and incorrect installation, we've prepared a side - by - side comparison. In the incorrect installation example, the brake disc shows signs of uneven wear after just 5,000 kilometers, with a maximum thickness difference of 0.2mm. In contrast, the correctly installed brake disc maintains a thickness difference of less than 0.05mm after 20,000 kilometers, demonstrating superior durability and performance.

According to a recent test report from an independent automotive testing agency, vehicles equipped with correctly installed brake discs have a 30% lower risk of brake - related accidents compared to those with poorly installed ones. In addition, our customers have reported that using our high - precision brake discs has extended their brake system's service life by an average of 20%.

"Since we switched to your brake discs and followed the correct installation procedures, the number of brake replacements in our fleet has decreased significantly, saving us a lot of maintenance costs." - A fleet manager

Choosing our high - precision brake discs is not just about replacing a component; it's an investment in driving safety. With our 2 - year warranty and 60,000 - kilometer guarantee, you can be confident in every brake application. Don't miss out on the opportunity to enhance your vehicle's braking performance and reliability. Click here to learn more about our high - quality brake discs!

We encourage you to leave your comments and questions in the section below. Our team of experts is always ready to assist you!