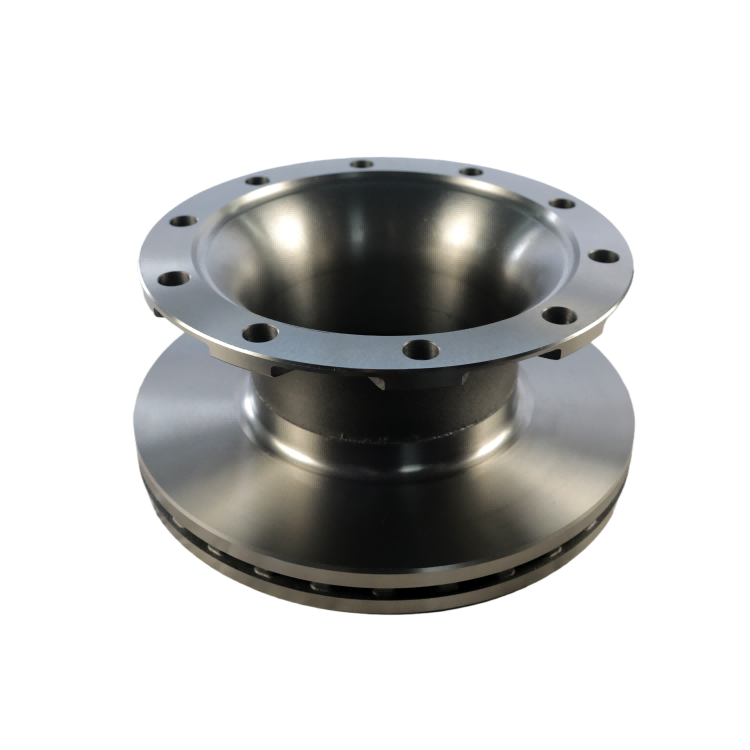

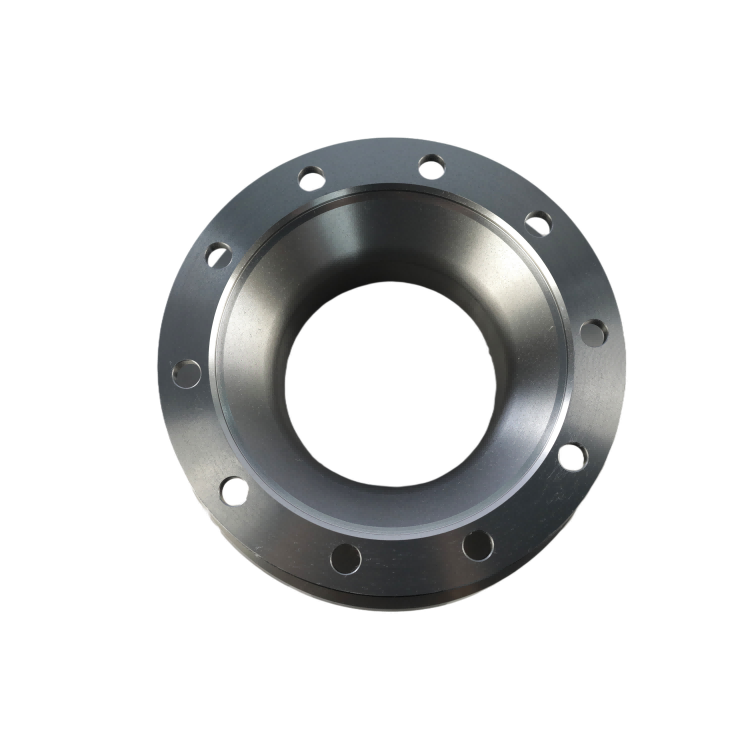

In the commercial vehicle industry, brake performance isn’t just about stopping power—it’s about consistent, predictable behavior over thousands of miles. A single misaligned brake disc can lead to vibration, noise, and even catastrophic failure. But here’s what many fleet managers overlook: the root cause often lies not in the disc itself, but in how it's installed—and more specifically, the precision of the 定位孔 (location holes) and the finishing process used.

According to a 2023 study by the European Automotive Safety Council, over 42% of premature brake disc failures stem from improper installation—not material defects. One key factor? Misalignment due to imprecise locating holes. When these holes deviate by as little as 0.1 mm from specification, it causes uneven pressure distribution across the disc surface during clamping, leading to warping and thickness variation beyond acceptable limits (±0.05 mm).

That’s where advanced machining—specifically high-precision turning followed by grinding—makes all the difference. Our engineers at LaiZhou Guanzhuo Trading Co., Ltd. use CNC-controlled processes that ensure flatness within ±0.02 mm and concentricity under 0.03 mm. This level of consistency directly translates to smoother braking, reduced wear, and longer service life—especially critical for long-haul trucks operating in extreme conditions.

A major logistics company in Germany reported a 37% reduction in brake-related maintenance costs after switching to discs with certified precision-machined locating holes and standardized installation procedures. Their technicians now follow a step-by-step guide that includes torque calibration, surface cleanliness checks, and alignment verification using laser tools—a protocol we’ve made publicly available on our website.

These aren’t just technical details—they’re safety imperatives. The ISO 13849-1 certification on our products ensures compliance with international standards for functional safety in braking systems, giving you peace of mind whether you're managing 10 or 1,000 vehicles.

We believe knowledge should be shared freely—especially when it comes to safety. That’s why we publish detailed guides, host live Q&A sessions, and encourage feedback from mechanics and fleet managers alike. Your input helps us improve both our products and our resources.

Discover how our precision-engineered brake discs reduce downtime, enhance driver confidence, and protect your investment—every mile.

Explore High-Precision Brake Disc Solutions