In the realm of commercial vehicle maintenance, brake disc installation is a critical task that directly impacts vehicle safety and performance. This article delves deep into the common mistakes during brake disc installation and the significance of turning processes, aiming to enhance the safety and stability of the braking system.

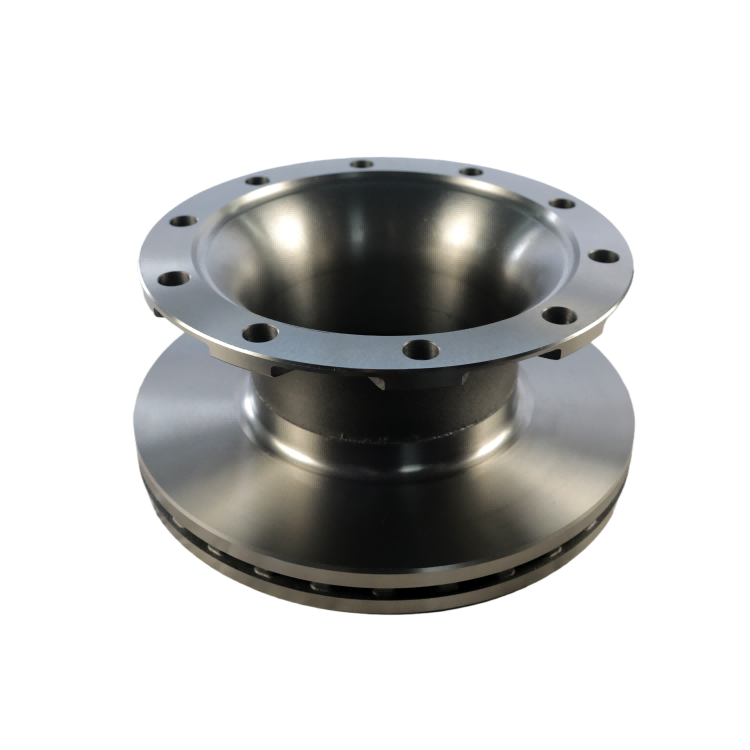

The precision of positioning holes in brake discs is crucial. Even a slight deviation in the positioning hole design can lead to improper installation, which may cause issues such as abnormal noises, vibrations, and even brake failure. For example, a study shows that about 30% of brake - related problems in commercial vehicles are due to inaccurate positioning hole installation. By understanding the importance of positioning hole precision, technicians can significantly improve the installation quality of brake discs.

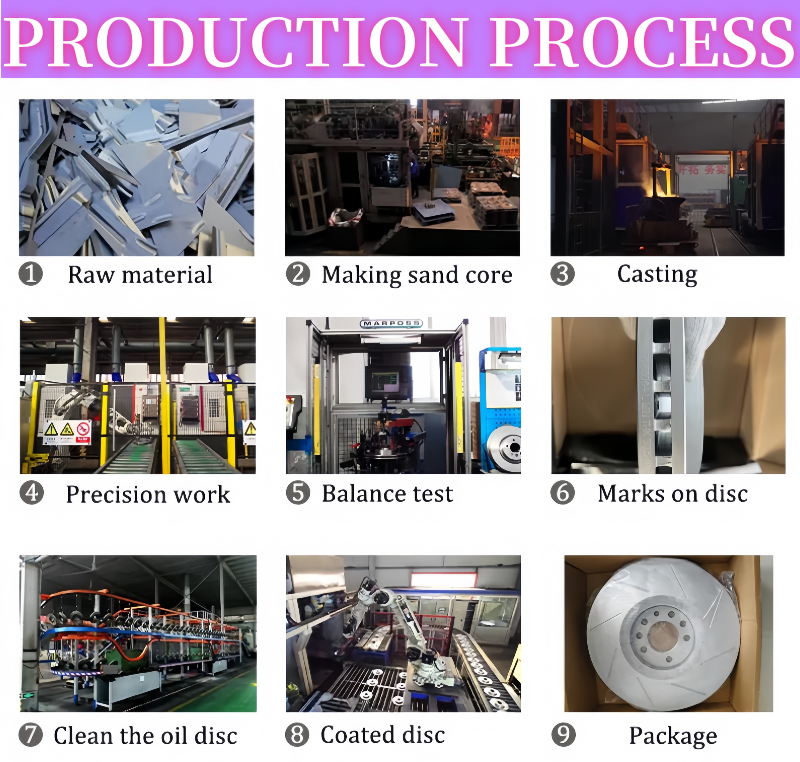

Turning and grinding processes play a vital role in ensuring the flatness and thickness consistency of brake discs. Turning can remove uneven material on the surface, while grinding can further refine the surface finish. These processes help to maintain the brake disc's surface within a tolerance range of ±0.05mm in thickness, ensuring stable braking performance. When the surface of the brake disc is flat and the thickness is consistent, it can effectively prevent problems caused by installation deviations.

This article uses graphic examples to show the standard installation process and common mistakes. The standard installation process includes steps such as cleaning the installation surface, using the correct tools to install the brake disc, and checking the installation accuracy. In contrast, common mistakes include improper tool use, ignoring positioning hole alignment, and not following the correct installation sequence. By comparing these two, front - line maintenance personnel and fleet managers can clearly understand the correct operation methods.

Using the right tools is essential for proper brake disc installation. Tools such as torque wrenches, alignment gauges, and cleaning brushes can help ensure accurate installation. This article provides detailed guidelines on how to use these tools correctly, enabling technicians to perform installations more efficiently and accurately.

To further illustrate the importance of correct brake disc installation and turning processes, this article includes real - world case analyses. For instance, a fleet of trucks reduced their brake - related maintenance costs by 40% after implementing the correct installation and maintenance procedures. These cases provide practical evidence of the benefits of following the correct methods.

In conclusion, understanding the installation mistakes and turning processes of commercial vehicle brake discs is crucial for improving the safety and stability of the braking system. By following the guidelines provided in this article, maintenance personnel and fleet managers can effectively reduce vehicle maintenance costs and accident risks.