Are you experiencing brake noise, vibration, or even reduced stopping power in your fleet? You're not alone. According to a 2023 study by the National Transportation Safety Board (NTSB), over 42% of commercial vehicle brake failures are linked to improper installation—not poor-quality parts. The real culprit? Often, it's a simple oversight: misaligned hub holes or inconsistent rotor surface finish due to subpar machining.

Let’s be honest—many technicians skip steps that seem “minor.” For example:

These aren’t just small errors—they’re safety risks. In fact, fleets reporting regular training on brake assembly see up to 30% fewer warranty claims related to installation issues (Source: Fleet Maintenance Magazine, Q2 2024).

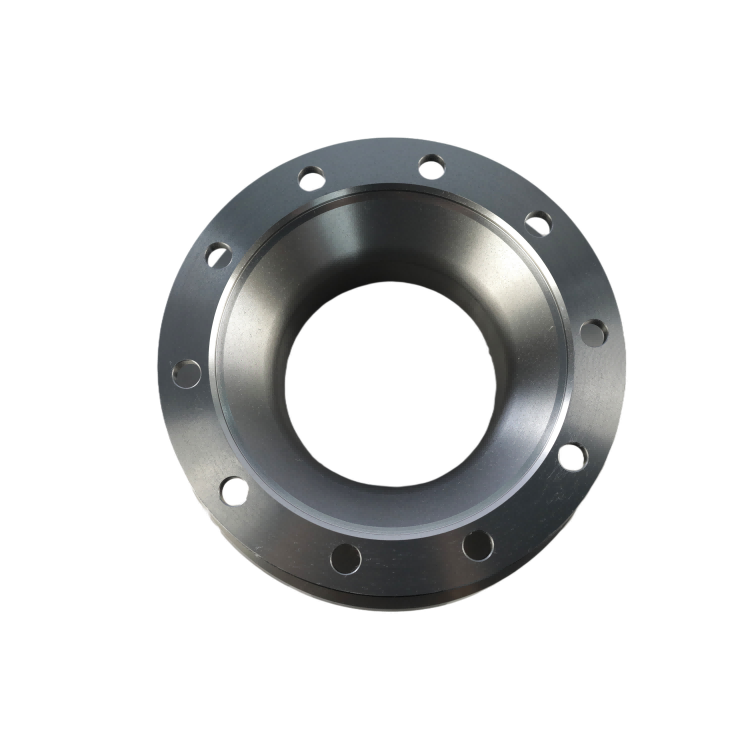

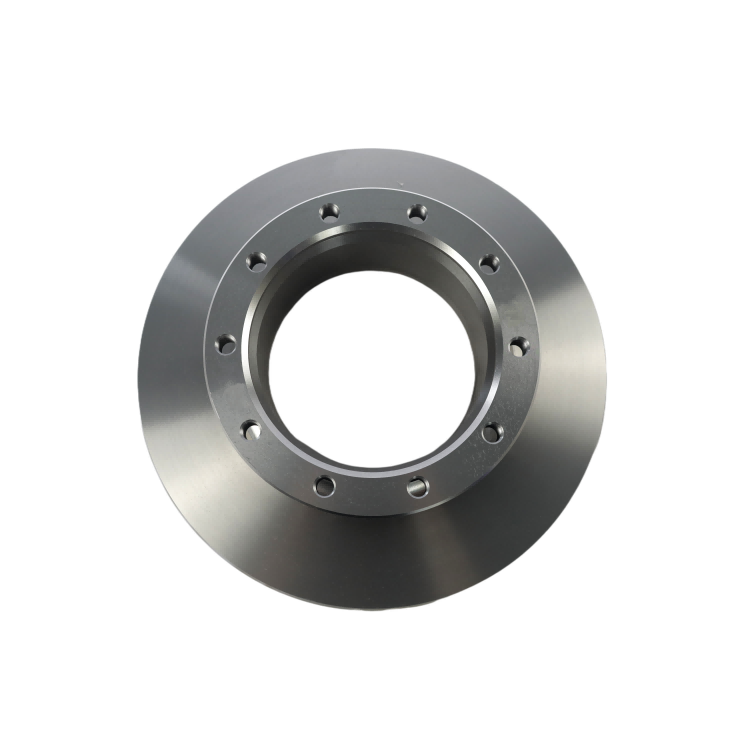

Brake rotors made from high-grade gray cast iron must undergo precision turning or grinding to ensure flatness within 0.02mm tolerance. This isn't just about smooth operation—it's about consistent friction and thermal stability under heavy loads. IATF TS16949-certified manufacturers follow strict process controls, including CNC-controlled lathe setups and in-process inspections at every stage.

Our own testing shows that rotors with optimized locating pin geometry reduce installation error rates by 30% compared to standard designs. Why? Because they guide the rotor into position automatically—no guesswork, no misalignment.

“After switching to your precision-engineered rotors, our mechanic team cut down rework time by 40%. We now have zero complaints about brake chatter.” – Carlos Mendez, Maintenance Manager, Midwest Trucking Co.

Follow this proven workflow:

If your team doesn’t do this regularly, consider a monthly refresher course. It pays off in both safety and cost savings.

Still unsure how to start? Try a pilot batch—install our rotors on one truck first. Monitor performance for 10,000 km. Then scale across your fleet. We offer full technical support, including free installation videos and downloadable checklists.

Whether you're managing a small fleet or a national logistics network, getting the basics right makes all the difference. Our high-precision brake rotors are engineered for longevity, safety, and ease of installation—backed by a 2-year warranty and expert support.

Download Free Installation Guide & Start Your Trial Today