When it comes to car modification, upgrading the brake kit is a crucial step that directly impacts your driving safety and performance. You might be wondering why it's so important. Well, a well - selected and properly installed brake kit can significantly enhance your vehicle's braking efficiency, reduce stopping distances, and provide a more stable driving experience.

You need to understand that different types of vehicles, such as passenger cars, commercial vehicles, and modified cars, have different requirements for brake kits. For passenger cars, you usually focus on comfort and daily driving safety. A brake kit with a good balance between smooth braking and noise reduction is ideal. In contrast, commercial vehicles often carry heavy loads, so they require brake kits with high - temperature resistance and strong braking force. Modified cars, on the other hand, may have unique performance goals, like high - speed racing or off - road driving, which demand brake kits that can handle extreme conditions.

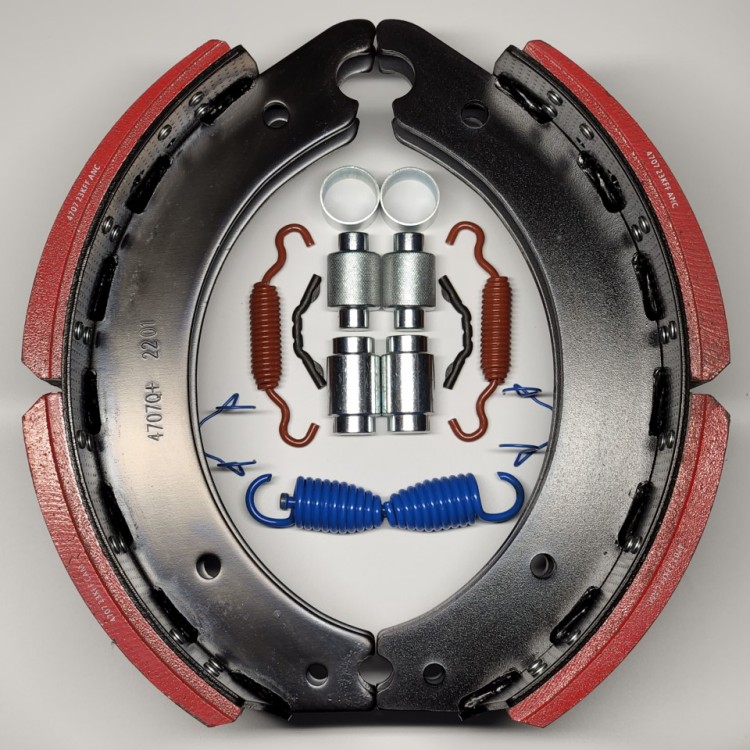

To choose the right brake kit, you must consider several key factors. First, look at the original factory parameters of your vehicle. These parameters, such as the braking system's pressure and flow rate, are the foundation for determining the compatibility of the brake kit. Second, the structure of your vehicle's wheels matters a lot. Different wheel sizes and offsets can affect the installation and performance of the brake kit. For example, if the wheel has a small inner diameter, it may not be able to accommodate a large - sized brake caliper. Third, the layout of the brake calipers is also crucial. The number of pistons in the caliper and their arrangement can influence the braking force distribution.

| Key Factors | Importance |

|---|---|

| Original Factory Parameters | Determine the basic compatibility of the brake kit |

| Wheel Structure | Affects the installation and clearance of the brake kit |

| Caliper Layout | Influences the braking force distribution |

Before installation, you should check the clearance between the brake components. Make sure there is enough space for the brake pads to move freely without rubbing against other parts. Rust prevention treatment is also essential. Applying anti - rust paint or coating can extend the service life of the brake kit. During installation, pay attention to the tightening torque specifications. Over - tightening or under - tightening the bolts can lead to serious problems, such as brake failure or component damage.

After installation, check the brake fluid level and ensure there are no leaks. Test the brake pedal feel. A spongy or overly hard pedal may indicate problems with the brake system. Also, check the ABS function if your vehicle is equipped with it. The ABS system plays a vital role in preventing wheel lock - up during braking.

Many people make mistakes when installing brake kits. One common mistake is using the wrong - sized brake pads. If the brake pads are too small, they won't provide enough braking force. Another mistake is ignoring the rust prevention treatment. Rust can corrode the brake components and reduce their performance. Some people also forget to follow the correct tightening torque specifications, which can lead to loose parts and potential safety hazards.

Expert Reminder: Avoiding these mistakes can save you from costly repairs and, more importantly, ensure your safety on the road.

When you choose the right brake kit and install it correctly, you can enjoy significant benefits. Your vehicle's braking performance will be greatly improved, with shorter stopping distances and more stable braking. This not only enhances your safety but also gives you more confidence when driving. Moreover, a well - installed brake kit can reduce wear and tear on other brake components, extending their service life and reducing maintenance costs.

Your car deserves more professional brake protection! Don't let a small oversight lead to big hidden dangers. To learn more about professional - grade brake system matching and construction techniques, click here.