Choosing and installing the correct brake kit for your commercial vehicle is crucial—not just for optimal braking performance but also for safety and longevity. Selecting the wrong brake kit can lead to costly maintenance, unexpected downtime, or worse, accidents. This guide breaks down the key points you need to consider when matching brake kits, from the hub structure to caliper layout, using real-world cases and practical checklists to help you avoid common mistakes and improve your vehicle’s braking efficiency.

Not all brake kits are created equal—passenger cars, commercial vehicles, and custom-modified trucks have vastly different braking demands. Commercial vehicles require brake kits designed to handle heavier loads, frequent stops, and rugged conditions. Recognizing these differences ensures that you select a brake kit that meets both the performance and safety standards your vehicle demands.

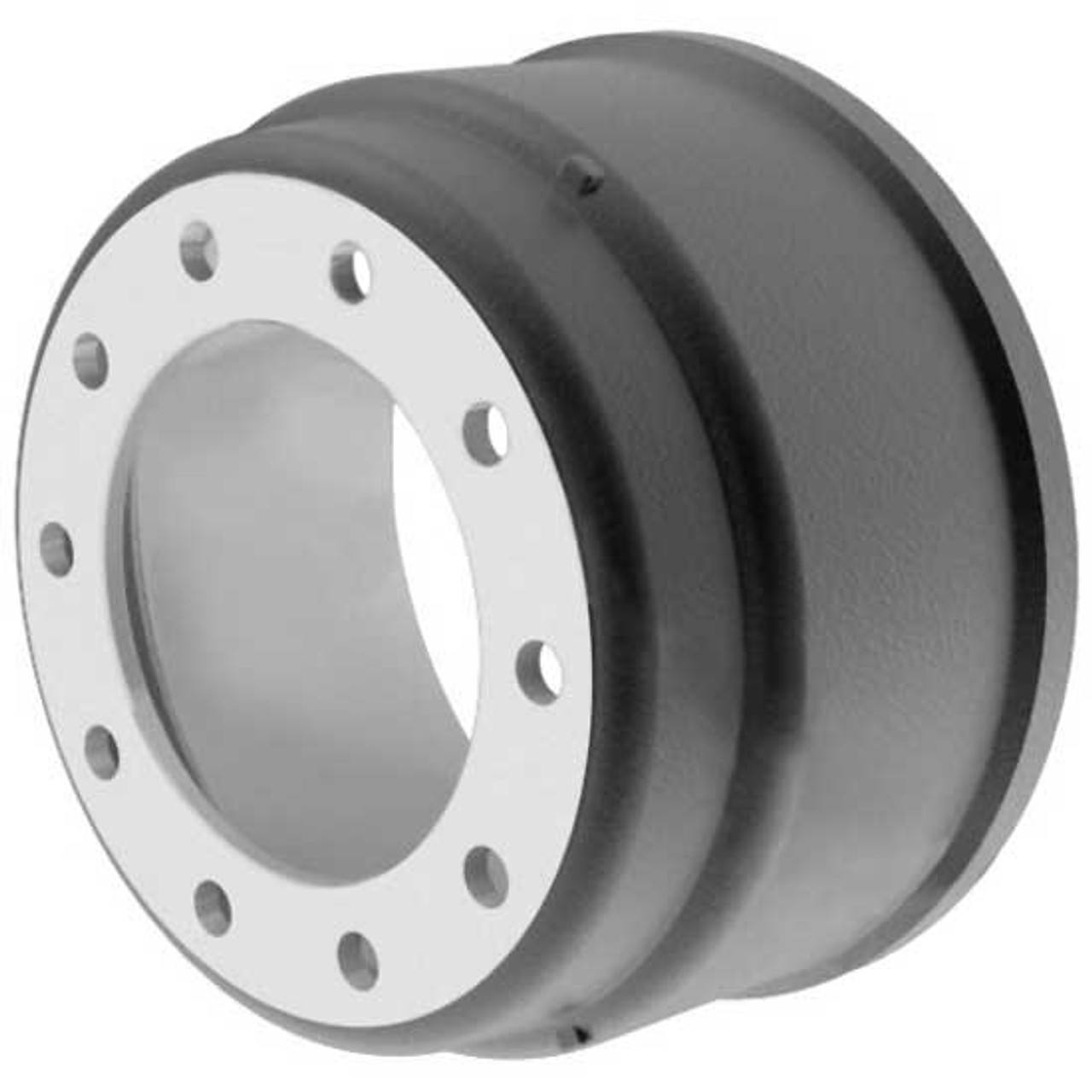

One of the most overlooked yet critical factors in brake kit installation is the compatibility of the brake components with the hub structure—specifically, the wheel's inner ring shape and size. The brake rotor and caliper must fit precisely within the hub’s contours. A mismatch can cause uneven wear or caliper binding, leading to reduced braking efficiency or mechanical failure.

To ensure a correct fit, cross-reference the hub dimensions and geometry against the brake kit specifications. OEM parameters are the most reliable sources for this data. For commercial vehicles, consider wheel diameter and offset, rotor thickness, and bolt patterns as part of the compatibility checklist.

The caliper must align perfectly with the rotor surface without interfering with other wheel components. Distances such as the caliper mounting bracket gap and piston travel range are vital. Incorrect caliper layout causes excessive drag or insufficient pad contact, both adversely affecting braking power and pad life.

Installing brake kits requires meticulous attention to technical details:

Consider a fleet operator who installed passenger car brake kits on heavy 12-ton trucks. Despite initial savings, the mismatched kits failed prematurely—rotor warping and caliper breakdowns caused unscheduled stops, increased repair costs, and safety hazards. Consulting precise hub and caliper specifications and opting for heavy-duty brake kits specifically designed for commercial use could have prevented these issues.

Many maintenance technicians overlook this differentiation. That’s why thorough technical understanding combined with quality products is key.

When it comes to ABS gear ring brake kits and comprehensive commercial vehicle brake solutions, Laizhou Guangze Trading Co., Ltd. stands out for delivering quality, durability, and expert service. Our products are engineered for precision fitment aligned with strict OEM standards, ensuring stable braking performance and reducing your after-sales risks.

From comprehensive consultation to supply chain support, we commit to helping you select the right brake kit tailored to your vehicle’s unique wheel hub and caliper layout needs.

Got doubts about your brake system installation? Encountered tricky fits with your last brake kit? Use the comments below to discuss your installation experiences or ask technical questions—whether you’re a fleet manager, technician, or enthusiast, sharing real-world insights enriches everyone’s knowledge.