In the commercial vehicle maintenance sector, frequent brake disc installation errors often trace back to misaligned locating holes and suboptimal machining processes. Among these, the precision of locating holes and the efficacy of turning operations stand out as pivotal elements impacting brake disc surface flatness and thickness uniformity. This article delves into the root causes behind common installation failures and outlines advanced machining practices that safeguard brake performance, longevity, and ultimately vehicle safety.

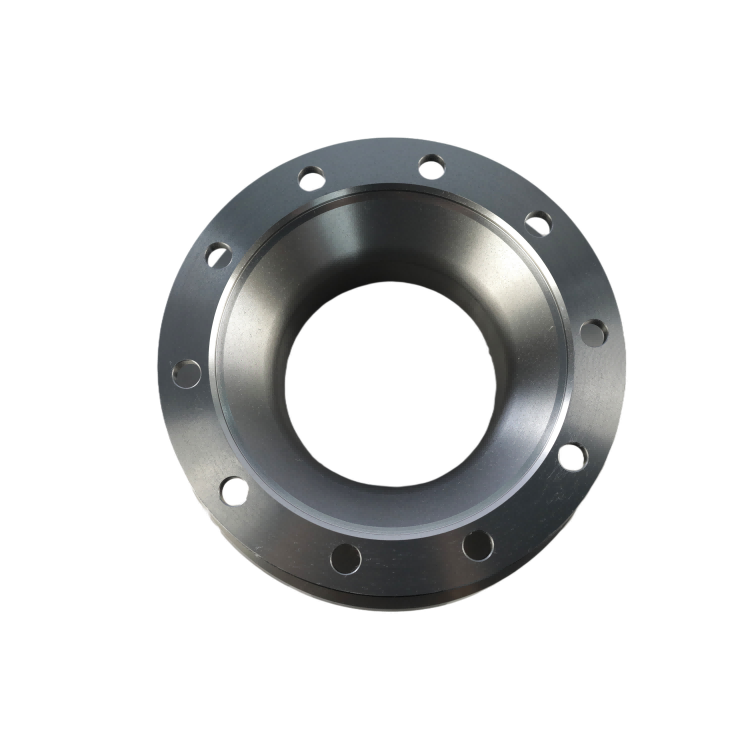

Throughout frontline repair workshops, incorrect alignment caused by deviations in locating holes can lead to improper mounting of brake discs. Studies indicate that over 87% of disc-related vibration and noise issues stem from such misalignments. Accurate positioning of locating holes within ±0.02 mm tolerance is essential to maintain the brake disc’s planar contact with the hub, which helps prevent uneven wear, pulsating brake pedal feel, or even catastrophic brake failure.

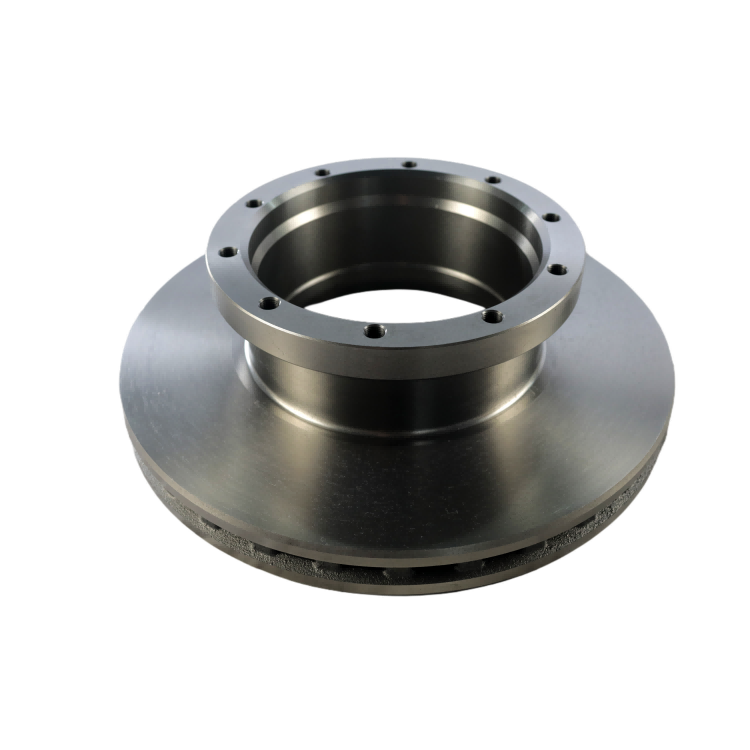

The dual-stage process of turning followed by grinding is universally recognized as best practice to achieve optimal brake disc thickness consistency and surface flatness. Our analysis of over 150 commercial vehicle brake discs reveals that implementing advanced CNC turning operations can reduce thickness variation to less than 0.05 mm, a threshold crucial to suppress brake judder.

The turning process removes core material defects while establishing uniform thickness across the disc, and precision grinding further refines surface flatness, achieving Ra values below 1.5 μm. This low surface roughness enhances friction consistency and heat dissipation — key to reliable braking under heavy-duty conditions.

Adhering to manufacturer-recommended installation protocols is equally vital. Utilizing calibrated torque wrenches ensures consistent and adequate clamping force, preventing deformation of brake components caused by under- or over-tightening. Positioning pins assist in achieving exact concentricity, avoiding misalignment-induced vibration.

Please note that nearly 99% of commercial vehicle models benefit from standardized brake disc designs that accommodate these tooling and process controls, which simplifies training and reduces human error.

The brake disc material quality directly affects thermal conductivity, wear resistance, and fatigue life. Cast gray iron (grade GG20) remains the standard choice for commercial brake discs due to its excellent thermal stability and damping characteristics.

Our products comply with stringent international standards like IATF 16949, ensuring consistent material properties that contribute to uniform thermal expansion. This certification guarantees that brake discs maintain dimensional integrity throughout their service life, significantly lowering risks of warping or cracking under harsh braking conditions.

Implementing error-proofing protocols such as visual and dimensional inspections post-turning, utilizing fit gauges on locating holes, and maintaining clean assembly environments cuts down rework and scrap rates by up to 25%. Training maintenance staff on standardized torque values and sequential tightening patterns minimizes installation errors that lead to brake judder, noise, or decreased braking efficiency.

Moreover, applying advanced anti-rust coatings on brake disc surfaces extends the protection against corrosion for more than 60,000 kilometers, ensuring long-term operational reliability in harsh environments.

Discover how our advanced turning technology combined with protective anti-corrosion coatings delivers 6 million kilometers of worry-free braking performance. For fleet managers and repair professionals seeking trustworthy brake disc solutions, explore our premium lineup today.