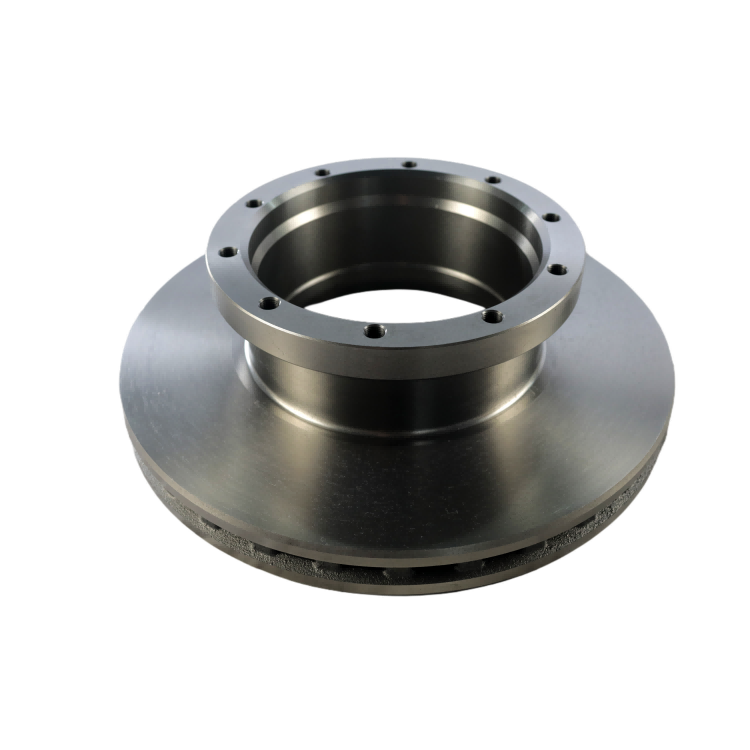

In the realm of commercial vehicle fleet management, brake system reliability stands as a non-negotiable factor directly influencing safety, operational efficiency, and maintenance costs. Among the critical components, the brake disc—the heart of the braking system—commands special attention. Common missteps during brake disc installation, specifically related to locating hole design and the precision of machining processes, often result in compromised brake performance, manifesting as noise, vibrations, or even brake failure. This article delves into the technical nuances of locating hole design and turning/grinding quality that collectively ensure brake disc flatness and uniform thickness, thereby safeguarding fleet braking performance and operational integrity.

A significant percentage of brake-related issues in commercial fleets—estimated at approximately 40% during routine maintenance audits—stem from improper installation techniques. Typically, technicians overlook the pivotal role that locating holes play in aligning the brake disc accurately during mounting. Misaligned or imprecisely machined locating holes can introduce uneven mounting pressure, resulting in disc runout beyond the industry standard threshold of 0.05 mm. This condition accelerates uneven wear and threatens brake system effectiveness.

Locating holes serve as the mechanical interface ensuring concentricity between the brake disc and the wheel hub. High-precision design requires adherence to tight dimensional tolerances, typically within ±0.02 mm, and optimized positioning relative to the disc’s center. This accuracy guarantees that the mounting forces are evenly distributed, minimizing stress concentration points.

Moreover, the selection of appropriate materials and manufacturing processes for the locating holes—including drilling followed by precision reaming—is crucial to prevent deformation during installation and operation. Incorporating such design rigor is integral to sustaining brake disc surface flatness and uniform thickness.

Following locating hole fabrication, the brake disc undergoes turning and grinding to achieve critical dimensional and surface finish specifications. The machining process targets flatness within 0.03 mm tolerance and uniform thickness variance of less than 0.02 mm across the friction surface.

Advanced CNC turning coupled with fine-grain surface grinding optimizes friction uniformity, which directly correlates to braking smoothness and resistance to vibration-induced noise. High-quality machining also prevents hotspots during braking, enhancing thermal stability and extending operational life.

Ensuring the benefits of precision locating holes and machining are realized in the field depends equally on correct installation procedures. A standardized approach integrates the following steps:

Tools such as dial indicators, calibrated torque wrenches, and micrometers are indispensable for achieving and validating installation quality, empowering maintenance teams to uphold fleet safety standards with confidence.

| Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Brake-Related Downtime (monthly hours) | 50 | 18 | 64% |

| Maintenance Cost per Vehicle ($) | 120 | 72 | 40% |

| Average Brake Pad Life (km) | 60,000 | 85,000 | 42% |

Practical knowledge transfer is vital for embedding these solutions into daily operations. Interactive training modules, including step-by-step visual guides and troubleshooting checklists, enhance technician confidence and reduce human errors. Additionally, digital platforms incorporating Q&A forums allow personnel to share experiences and glean insights from peer discussions, fostering a community focused on continuous improvement and safety performance.

Selecting brake discs from a trusted supplier amplifies the impact of precision design and machining. Laizhou Guanpeng Trading Co., Ltd. offers a premium range of commercial vehicle brake discs crafted under stringent quality controls with a focus on locating hole accuracy and surface machining excellence. Backed by responsive after-sales support including warranty coverage, technical consultation, and prompt replacement services, customers are assured of sustained brake system reliability and safety.

Ready to upgrade your fleet’s brake safety with precision-engineered brake discs and expert support? Discover Laizhou Guanpeng’s High-Quality Brake Discs Now and experience dependable braking performance tailored for your commercial vehicles.

Readers are encouraged to share their installation experiences or questions in the comment section below. Join the conversation and contribute to elevating the standards of fleet brake safety worldwide.

.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)