In the realm of commercial vehicle maintenance, the quality of brake discs is of paramount importance for ensuring driving safety. Among the various factors affecting brake disc performance, the consistency of thickness plays a crucial role. This article delves into the key role of turning and grinding processes in ensuring the thickness consistency of commercial vehicle brake discs, with a focus on the impact of positioning hole accuracy on brake disc installation.

A brake disc with consistent thickness can provide more stable braking performance. According to industry research, a deviation in brake disc thickness of more than 0.05mm can lead to uneven braking force, which may cause vibrations and noise during braking. In severe cases, it can even affect the vehicle's handling and safety. Therefore, ensuring the thickness consistency of brake discs is essential for improving the overall performance of the braking system.

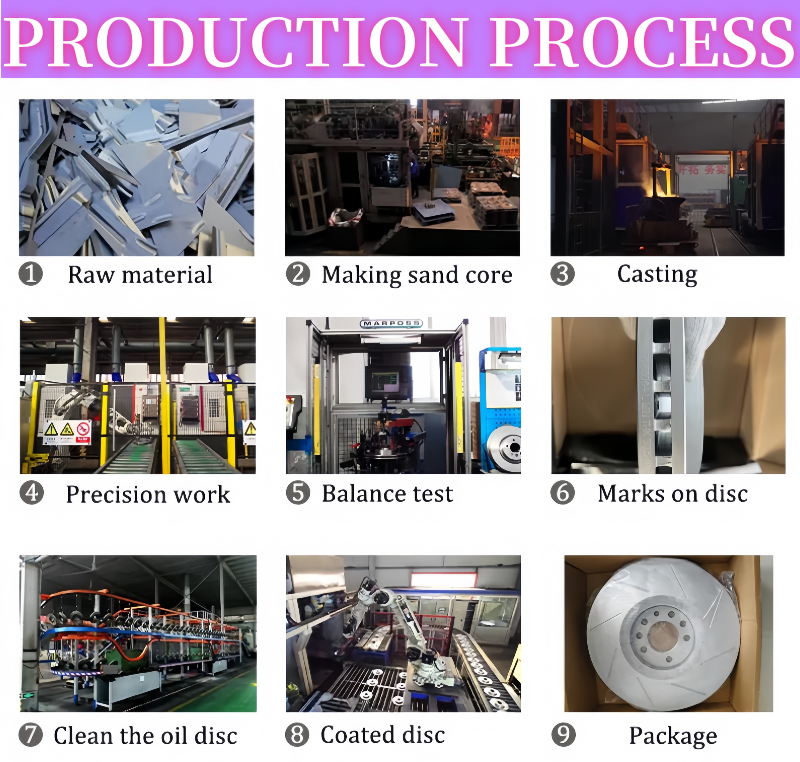

Turning and grinding are two important machining processes for brake discs. Turning can remove the outer layer of the brake disc to correct its shape and size, while grinding can further improve the surface finish and thickness accuracy of the brake disc. Through these two processes, the thickness deviation of the brake disc can be controlled within a very small range, usually within 0.02mm.

For example, in a large - scale commercial vehicle maintenance center, after using advanced turning and grinding equipment, the proportion of brake discs with thickness deviation within the standard range increased from 70% to 90%. This shows that high - quality machining can effectively improve the thickness consistency of brake discs.

The accuracy of positioning holes on brake discs is also a critical factor affecting installation quality. If the positioning holes are not accurate, the brake disc may not be installed correctly, which can lead to problems such as uneven wear and reduced braking efficiency. In fact, statistics show that about 15% of brake disc installation failures are caused by inaccurate positioning holes.

There are several common installation mistakes in the industry. For instance, some technicians may not clean the mounting surface thoroughly, which can lead to poor contact between the brake disc and the hub. Another common mistake is using incorrect installation tools, which may damage the brake disc or cause inaccurate installation.

To avoid these mistakes, it is necessary to follow standardized installation procedures. First, clean the mounting surface and positioning holes carefully. Second, use the correct installation tools and follow the recommended torque values. By doing so, the installation quality of brake discs can be significantly improved.

High - quality brake discs not only provide better braking performance but also have a longer service life. A well - machined brake disc can reduce the frequency of replacements, which in turn reduces maintenance costs for fleet managers. Additionally, it can enhance the overall safety of the vehicle, protecting the lives of drivers and passengers.

When it comes to high - quality commercial vehicle brake discs, Laizhou Guanzuo Trading Co., Ltd. stands out. Their brake discs are manufactured using advanced turning and grinding processes, ensuring excellent thickness consistency and high - precision positioning holes. With strict quality control, these brake discs can meet the highest standards of the industry.

Don't compromise on the safety and performance of your commercial vehicles. Choose Laizhou Guanzuo Trading Co., Ltd.'s high - quality brake discs and experience the difference. Click here to learn more about our premium brake disc products!