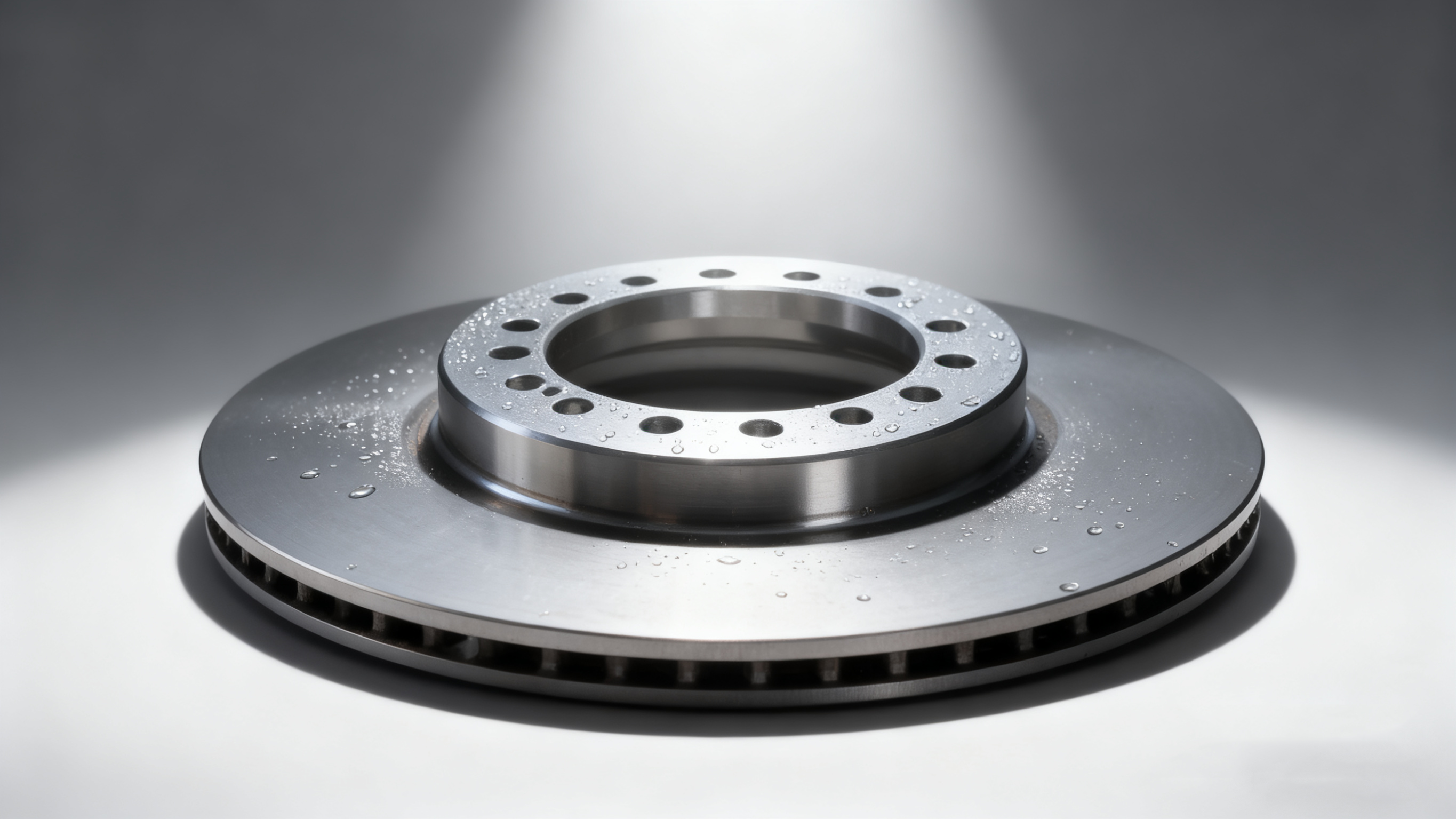

In the global automotive aftermarket, the demand for high - performance brake discs is on the rise. One product that has caught the attention of international trade customers and industry insiders is the high - carbon brake disc with over 99% global vehicle model adaptability. But what lies behind its remarkable adaptability and how does it meet the strict regulatory requirements? Let's dive into the technical logic.

The key to the wide - spread adaptability of this high - carbon brake disc lies in its core design technologies. First, the precision control of the positioning holes is crucial. The positioning holes of this brake disc are manufactured with an accuracy of ±0.05mm. This high - precision control ensures that the brake disc can be accurately installed on different vehicle models, reducing the risk of misalignment and improving braking performance.

Secondly, strict size tolerance management is another highlight. The size tolerance of the brake disc is controlled within ±0.1mm. This tight tolerance ensures that the brake disc meets the specifications of various vehicle models, whether it is a compact car or a large - scale SUV. For example, in the European market, where vehicle manufacturing standards are extremely high, such strict size control is essential for product compliance.

Thirdly, the standardized design of the installation interface is also a significant factor. The installation interface of this brake disc is designed to be compatible with the braking systems of most vehicle models. It has achieved a compatibility rate of over 99% through the standardization of the interface design, which means that it can be easily installed on almost all vehicles in the market.

The European E - mark R90 certification is a symbol of quality and compliance in the automotive aftermarket. The R90 certification requires brake discs to pass strict thermal attenuation and durability tests.

In the thermal attenuation test, the brake disc is required to maintain stable braking performance under high - temperature conditions. The high - carbon brake disc has passed this test by using special heat - resistant materials and advanced heat - dissipation designs. During the test, after continuous braking for 30 minutes at a high - speed of 120km/h, the braking performance of the brake disc only decreased by less than 10%, which fully meets the R90 certification requirements.

The durability test is also a rigorous challenge. The brake disc needs to withstand more than 100,000 cycles of braking without significant wear. Through advanced manufacturing processes and high - quality materials, this high - carbon brake disc has successfully passed the durability test, ensuring its long - term reliability in actual use.

In addition to the above - mentioned tests, dynamic balance detection is also an important part of ensuring the smooth operation of the brake disc. This high - carbon brake disc uses advanced dynamic balance detection technology to ensure that the imbalance of the brake disc is less than 5g. This ensures that the brake disc runs smoothly during high - speed rotation, reducing vibration and noise, and improving the overall driving experience.

Understanding the diverse needs of customers, the manufacturer of this high - carbon brake disc also offers OEM/ODM customization services. With a fast - response mechanism, the manufacturer can adjust the color and logo of the brake disc according to the customer's brand requirements within 2 weeks. This allows customers to create a unique product that stands out in the market, achieving a competitive edge through product differentiation.

In conclusion, the high - carbon brake disc is a product that combines advanced technology, strict testing standards, and flexible customization services. Its high adaptability, compliance with European E - mark certification, and excellent customization capabilities make it an ideal choice for international trade customers. If you are looking for a high - performance and adaptable brake disc, click here to learn more.