In the global B2B market, selecting the right brake kit is crucial for ensuring vehicle safety and performance. This article aims to provide a comprehensive guide on how to effectively identify the compatibility and quality standards of brake kits, addressing the pain points faced by global buyers.

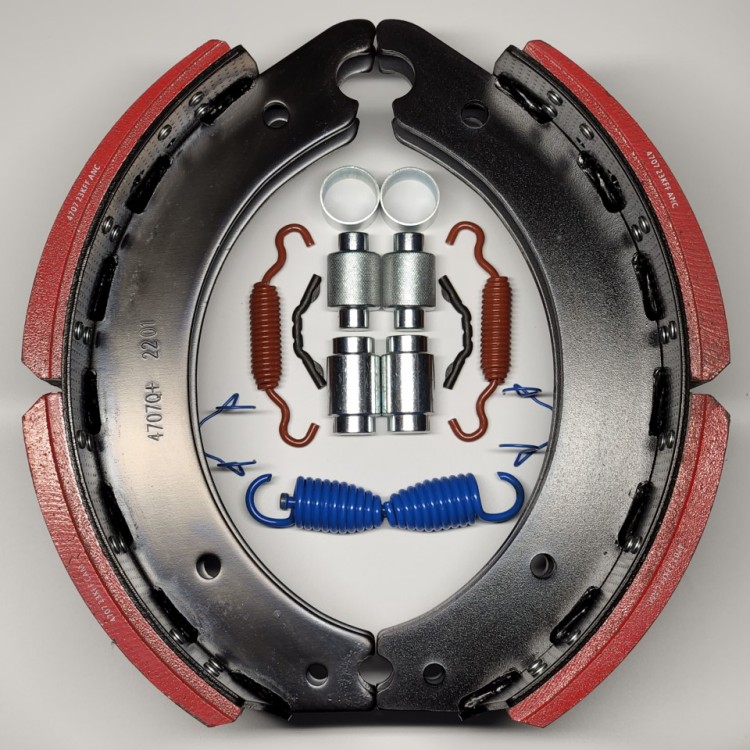

There are various types of brake kits available in the market, each designed for specific vehicle types and scenarios. For instance, single-piece brake kits are commonly used in standard passenger cars due to their cost - effectiveness and reliability. Two - piece brake kits, on the other hand, are more suitable for high - performance vehicles and racing cars, as they offer better heat dissipation and reduced weight. Coated brake kits are ideal for vehicles in harsh environments, providing enhanced corrosion resistance.

Table 1: Brake Kit Types and Their Applicable Vehicles

| Brake Kit Type | Applicable Vehicle Types | Typical Scenarios |

|---|---|---|

| Single - piece | Passenger cars | Daily commuting |

| Two - piece | High - performance cars, racing cars | Track racing |

| Coated | Vehicles in harsh environments | Off - road driving, coastal areas |

Determining the compatibility of a brake kit is a complex process that requires careful consideration of multiple factors. One of the most important aspects is comparing the original equipment manufacturer (OEM) parameters. By referring to the vehicle's service manual or contacting the manufacturer, buyers can obtain accurate information about the brake system, such as disc diameter, thickness, and bolt patterns.

The shape of the wheel hub inner ring also plays a significant role. A mismatched hub inner ring can lead to improper installation and reduced braking performance. Additionally, the position of the brake caliper relative to the disc is crucial. Incorrect caliper positioning can cause uneven wear on the brake pads and discs, shortening their lifespan.

Proper installation is essential for the optimal performance of brake kits. Before installation, a thorough inspection of all components is necessary to ensure there are no damages or defects. During the installation process, attention should be paid to gap adjustment. The gap between the brake pads and the disc should be within the specified range to ensure efficient braking.

Rust prevention treatment is also important, especially for brake components exposed to the elements. Applying anti - rust coatings can significantly extend the lifespan of the brake kit. Moreover, following the correct torque specifications when tightening bolts is crucial to prevent loose connections, which can be extremely dangerous.

Here is a simple installation checklist:

Many buyers and installers make common mistakes when selecting and installing brake kits. One of the most frequent errors is choosing a kit based solely on price without considering compatibility. This can lead to serious safety issues, such as reduced braking efficiency and increased stopping distances.

Let's take a look at a real - life case. A repair shop in Europe installed a mismatched brake kit on a passenger car. Due to the incorrect caliper position, the brake pads wore unevenly, and the driver experienced a significant decrease in braking performance. After replacing the correct brake kit, the braking performance was restored.

We encourage you to share your questions and experiences regarding brake kit selection and installation. Our team of experts will be happy to answer your queries and provide further guidance.