In the realm of commercial vehicle safety, the brake disc stands as a pivotal component dictating braking reliability and longevity. Addressing the prevalent challenges of wear and corrosion, Laizhou Guanzhi Trading Co., Ltd. introduces a high-performance wear-resistant and rust-proof brake disc designed to elevate commercial vehicle brake systems to new heights of precision and durability.

Brake discs in commercial vehicles endure harsh operating conditions that result in accelerated wear and corrosion. Common issues include friction-induced surface degradation and rust formation due to exposure to moisture and road salts. These challenges compromise braking efficiency, lead to unstable deceleration, and increase maintenance costs. Industry data indicate that brake component wear accounts for over 30% of unscheduled commercial vehicle downtime, directly impacting fleet safety and operational costs.

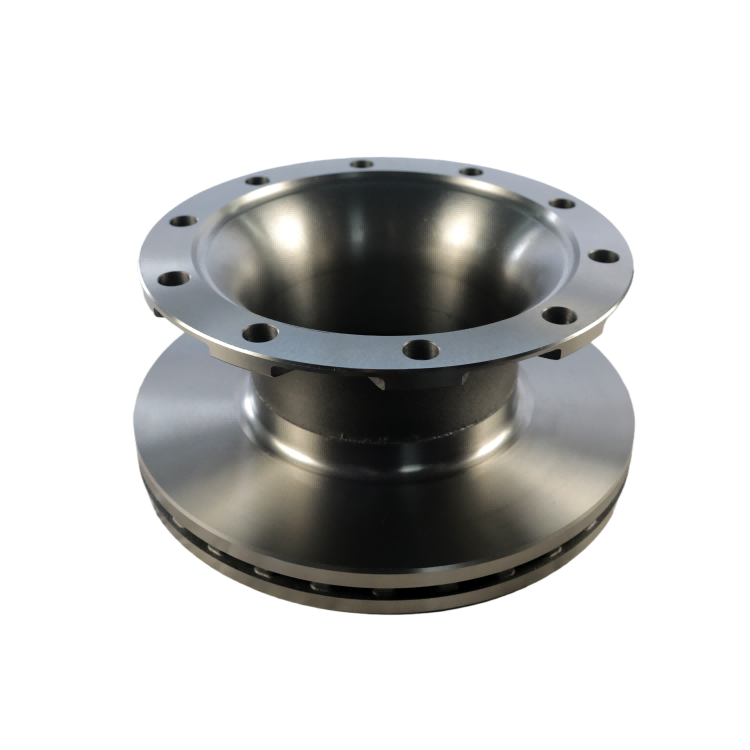

Leveraging premium-grade materials such as high-quality gray cast iron, GG20 grade, and high-carbon steel, Laizhou Guanzhi’s brake discs exhibit exceptional hardness and thermal conductivity. These materials resist surface cracking and deformation under heavy braking loads, ensuring dimensional stability.

Complementing material choice, advanced mechanical processing techniques—including CNC precision machining and dynamic balancing—enhance the rotational stability and uniform wear patterns of the discs. Dynamic balance detection ensures vibrations are minimized, supporting consistent brake pedal feel and safeguarding the wheel bearings.

The application of multi-layer anti-rust coatings significantly extends the life cycle of brake discs. Each coating layer serves a specific function—from primer adhesion to topcoat protection—resulting in enhanced resistance against oxidation, salt spray, and humidity. Independent lab tests demonstrate up to a 50% improvement in corrosion resistance compared to conventional brake discs.

This protective system not only maintains the aesthetic integrity of the brake disc but also prevents pitting and structural degradation which could undermine braking safety.

Compliance with rigorous industry standards underpins the trustworthiness of Laizhou Guanzhi’s brake discs. Key certifications including IATF TS16949 (automotive quality management), R90 E-mark (European brake safety), and VCA COP (vehicle certification authority) assure global markets of product reliability and regulatory alignment.

These certifications affirm that each rotor meets stringent requirements for mechanical strength, thermal performance, and material consistency, facilitating compatibility with 99% of global commercial vehicle models.

Beyond product excellence, Laizhou Guanzhi extends professional customer support featuring custom branding options, scalable packaging solutions, two-year warranty coverage, and mileage assurance. This comprehensive after-sales package fosters enhanced client confidence and ensures fast, responsive technical assistance.

This tailored approach supports fleet operators and parts distributors in maintaining continuous brake system performance while optimizing inventory management.