In the field of commercial vehicle maintenance, the installation of brake discs is a crucial task that directly affects the safety and performance of the vehicle. However, there are often many misunderstandings in the installation process, which can lead to various problems such as abnormal noises, vibrations, and even brake failure. This article will conduct an in - depth analysis of these common mistakes and recommend high - quality brake discs.

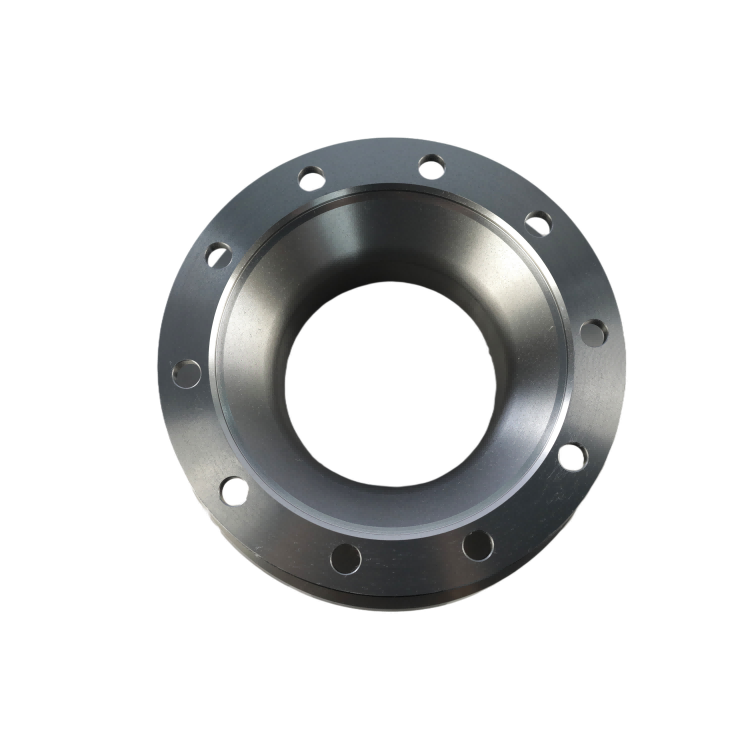

One of the most common mistakes is the lack of attention to the precision of the positioning holes. According to relevant statistics, about 30% of brake disc installation problems are related to inaccurate positioning holes. When the positioning holes are not accurate, the brake disc cannot be properly installed, which will cause uneven stress on the brake system during operation. As a result, the braking performance will be significantly reduced, and the service life of the brake disc will also be shortened.

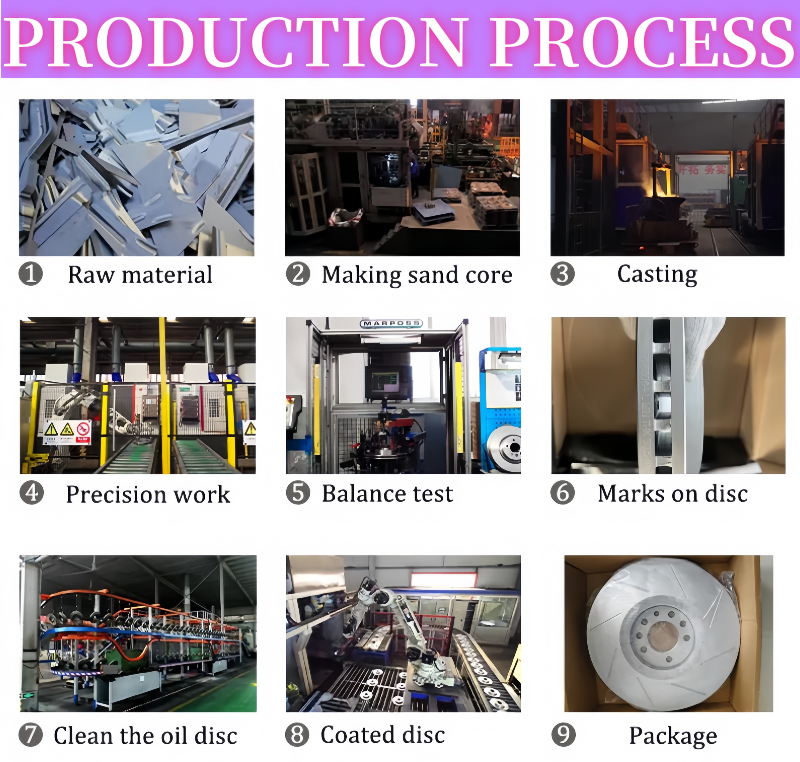

Another mistake is the neglect of turning and grinding processes. In fact, these two processes play a vital role in ensuring the flatness and thickness consistency of the brake disc. Without proper turning and grinding, the brake disc may have uneven surfaces, which can lead to vibrations and abnormal noises during braking. In severe cases, it may even cause brake failure, posing a serious threat to the safety of the vehicle and its passengers.

Machining, including turning and grinding, is the key to ensuring the flatness and thickness consistency of the brake disc. Through precise turning, the surface of the brake disc can be made smooth, and the thickness can be controlled within a very small error range. For example, the thickness error of a high - quality brake disc after turning and grinding should be controlled within ±0.05mm. This high - precision machining can effectively reduce the risk of abnormal noises and vibrations, and ensure the stability and safety of the brake system.

Let's take a real - world case as an example. A logistics company once had a high incidence of brake problems in its commercial vehicle fleet. After in - depth inspection, it was found that the main reason was the poor flatness and thickness consistency of the brake discs caused by improper machining. After replacing the brake discs with those that had undergone strict machining processes, the brake problems were significantly reduced, and the safety of the vehicles was greatly improved.

To ensure the correct installation of brake discs, standardized installation steps and the use of appropriate tools are essential. First, before installation, the installation surface of the brake disc and the hub should be thoroughly cleaned to remove any dirt or debris. Then, use a torque wrench to tighten the bolts to the specified torque value. For most commercial vehicle brake discs, the tightening torque should be between 80 - 120 Nm.

In addition, some specialized tools such as a micrometer can be used to measure the thickness of the brake disc to ensure its thickness consistency. By following these standardized steps and using the right tools, front - line maintenance personnel can improve their operational standardization and reduce the occurrence of installation errors.

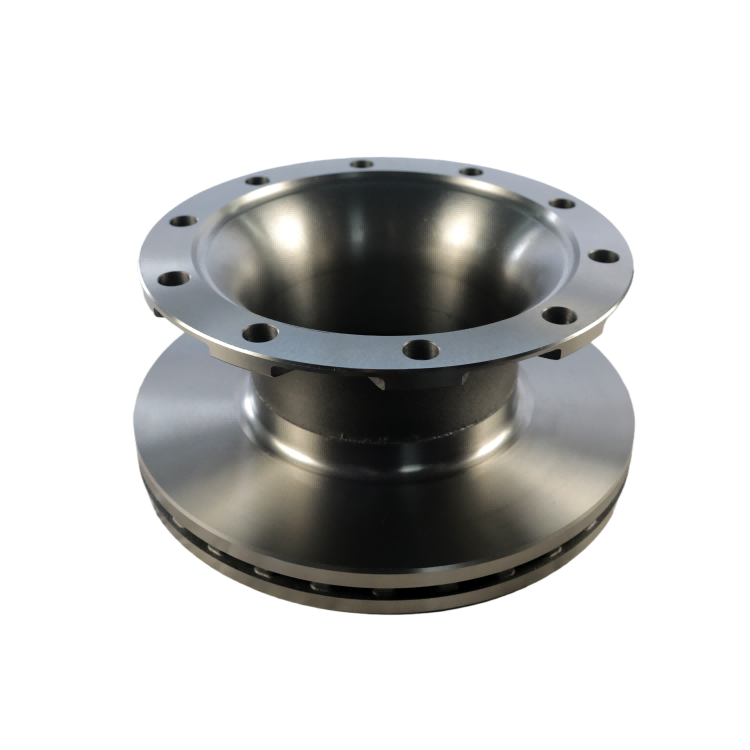

In addition to the above - mentioned aspects, anti - rust technology and international certifications are also important factors in evaluating the quality of brake discs. Advanced anti - rust technology can effectively prevent the brake disc from rusting, especially in humid or harsh environments. For example, some high - quality brake discs use a special anti - rust coating, which can extend the service life of the brake disc by more than 50%.

International certifications such as ISO 9001 and TS 16949 are also important guarantees of product quality. These certifications indicate that the product has met strict international quality standards, which can enhance users' confidence in the product.

Based on the above analysis, we recommend the high - quality brake discs of Laizhou Guanzuo Trading Co., Ltd. These brake discs have high - precision positioning holes, and they have undergone strict turning and grinding processes to ensure flatness and thickness consistency. At the same time, they are treated with advanced anti - rust technology and have obtained international certifications, which can effectively improve the braking safety and performance of commercial vehicles.

Moreover, Laizhou Guanzuo Trading Co., Ltd. also provides excellent after - sales service. If you have any questions or problems during the use of the brake discs, their professional after - sales team will provide you with timely and effective solutions.

We encourage you to leave your comments and share your experiences in the comment section below. Your feedback is very important to us, and we will continue to optimize our content based on your suggestions. If you are interested in our recommended high - quality brake discs, click here to learn more and make a purchase!