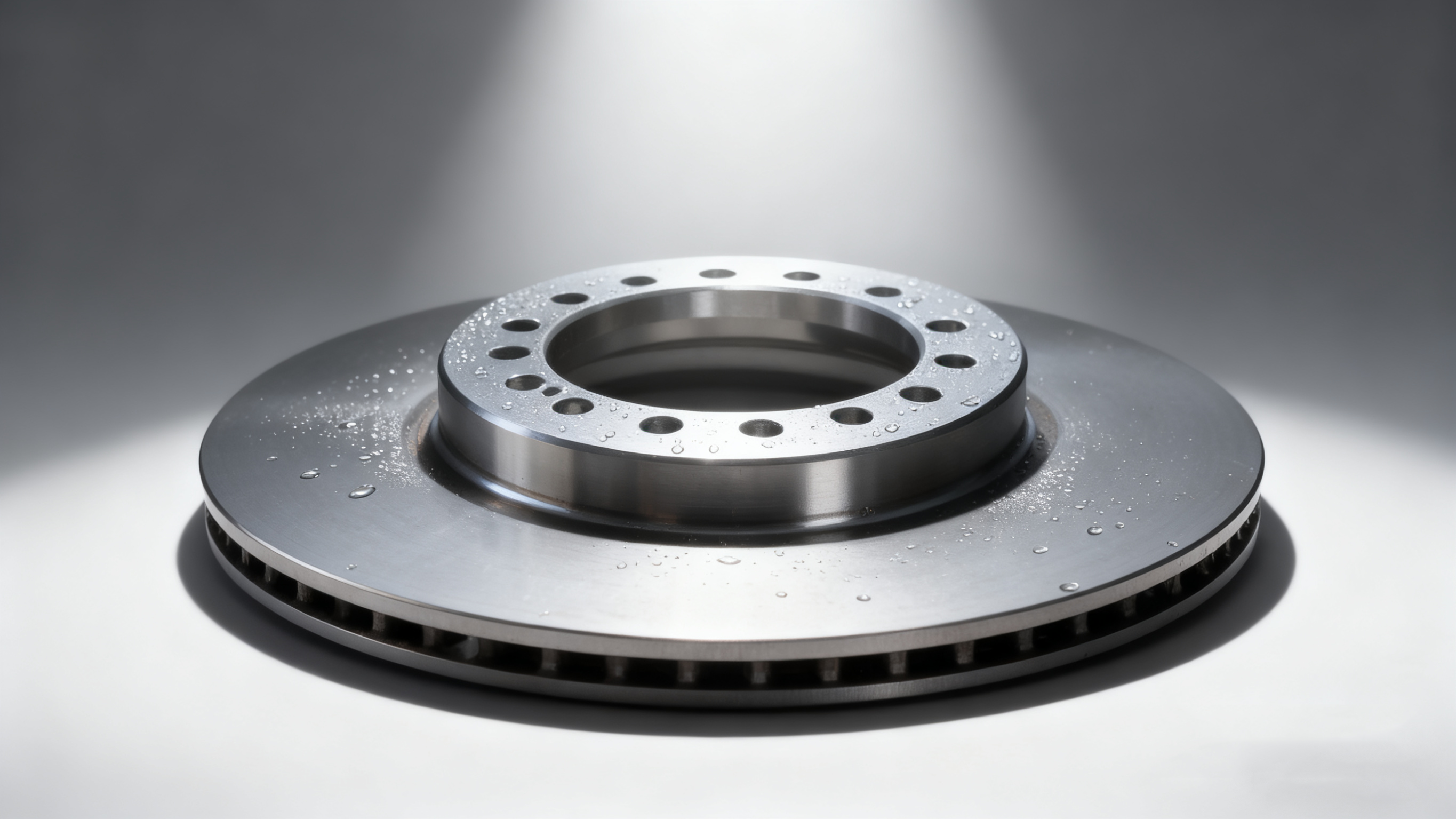

As a frontline maintenance technician or fleet manager, you understand the critical role that brake discs play in ensuring the safety and performance of commercial vehicles. However, there are common misconceptions in brake disc installation that can lead to a range of problems, from annoying noises and vibrations to potentially life - threatening brake failures. In this article, we'll delve deep into these issues and introduce you to the high - quality brake discs offered by Laizhou Guanzuo Trading Co., Ltd.

Many technicians and managers may overlook the importance of precise installation. For example, some may not pay enough attention to the accuracy of the positioning holes or the quality of turning and grinding processes. A study shows that approximately 30% of brake - related issues in commercial vehicles stem from improper installation, including incorrect positioning and sub - standard machining.

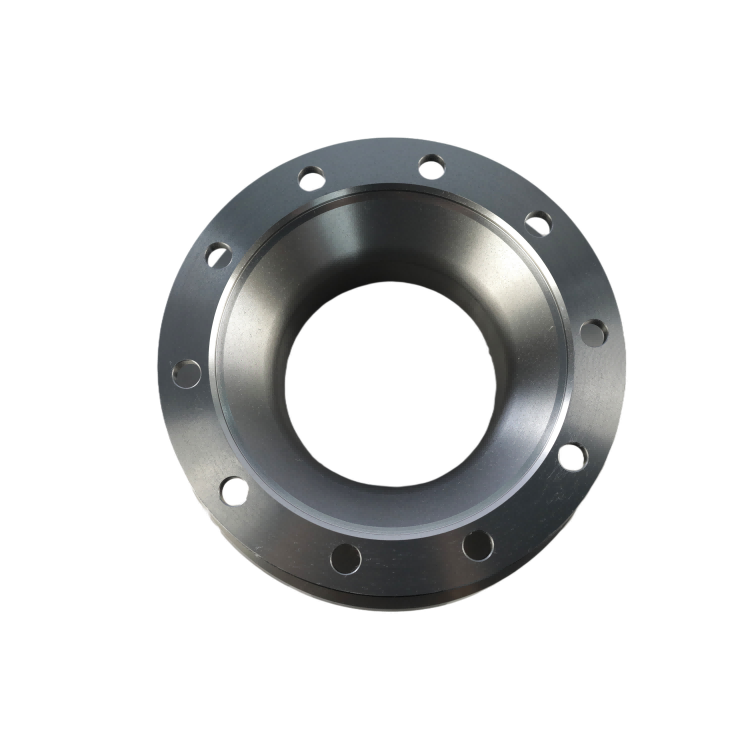

The accuracy of the positioning holes is crucial for the proper alignment of the brake disc. Even a small deviation can cause uneven wear, leading to vibrations and noise during braking. High - precision turning and grinding processes ensure the flatness and thickness consistency of the brake disc. When the brake disc has a flat surface and consistent thickness, it can distribute the braking force evenly, which is essential for effective and safe braking.

High - precision machining uses advanced equipment to ensure that the brake disc meets strict quality standards. For instance, computer - controlled machines can achieve a positioning hole accuracy within ±0.05mm, which is far more precise than manual operations. This level of precision guarantees that the brake disc fits perfectly with other components of the braking system, reducing the risk of brake failure.

Let's take a look at the differences between standard installation and common mistakes through a side - by - side comparison. In the standard installation process, technicians use specialized tools to measure and align the brake disc accurately. They also follow a strict sequence of steps to ensure that every component is installed correctly. On the contrary, common mistakes include using improper tools, skipping important steps, and not checking the accuracy of the installation.

For frontline maintenance technicians and fleet managers, here are some professional installation steps. First, clean the mounting surface thoroughly to remove any dirt or debris. Then, use a precision measuring tool to check the accuracy of the positioning holes. Next, install the brake disc using the recommended torque values. As for tools, we recommend using a high - precision torque wrench and a professional alignment tool. These tools can help you achieve a more accurate and reliable installation.

To further illustrate the importance of proper brake disc installation, let's look at some real - world cases. A large fleet management company once experienced a high rate of brake - related breakdowns. After a detailed investigation, it was found that improper installation was the main cause. After implementing the correct installation procedures and using high - quality brake discs from Laizhou Guanzuo Trading Co., Ltd., the breakdown rate dropped by 40% within six months.

Laizhou Guanzuo Trading Co., Ltd. offers high - quality brake discs that are designed with strict attention to positioning hole accuracy and machining quality. Our brake discs are made from high - grade materials and undergo multiple quality control checks. By choosing our products, you can ensure the safety and performance of your commercial vehicles, and reduce the maintenance costs in the long run.

We encourage you to leave your comments and questions below. Your feedback is valuable to us, and we'll use it to continuously improve our content and products. If you're interested in our high - quality brake discs, click here to learn more and place an order.