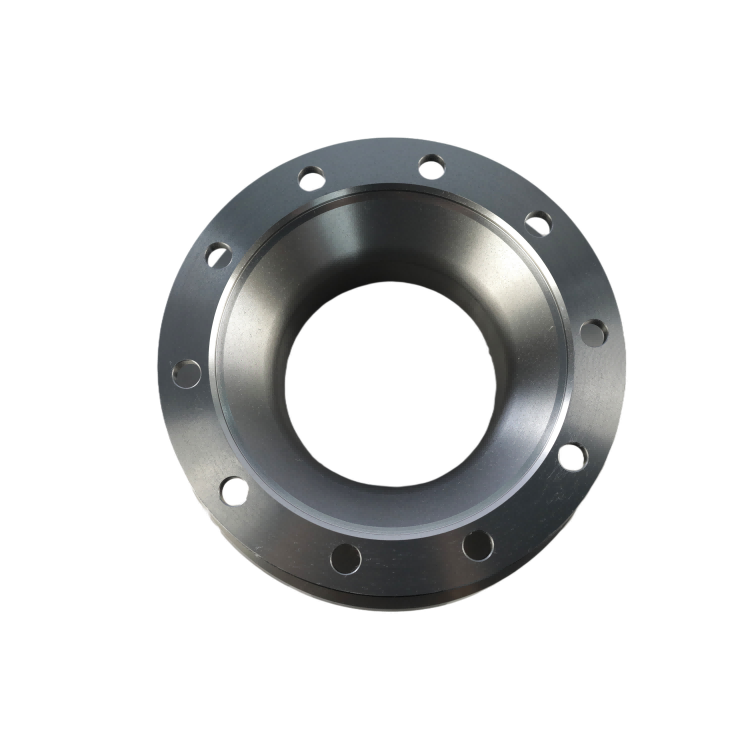

In the modern automotive market, the performance and compatibility of brake discs are under high - standard scrutiny. Laizhou Guanzhao Trading Co., Ltd. has introduced high - performance, wear - resistant, and rust - proof brake discs designed to fit 99% of passenger and commercial vehicle models, catering to the diverse needs of the global market.

The brake discs are crafted from high - quality gray iron, GG20, and high - carbon steel. Gray iron offers excellent heat dissipation, which is crucial during high - speed braking. GG20, with its good mechanical properties, ensures the structural integrity of the brake disc. High - carbon steel further enhances the hardness and wear resistance of the brake disc. These materials are the foundation for the high performance of the brake discs.

Combined with advanced machining and dynamic balancing technology, the brake discs guarantee precise and stable braking performance. Advanced machining ensures the smooth surface and accurate dimensions of the brake discs, while dynamic balancing technology eliminates vibrations during braking, which not only improves the braking feel but also extends the service life of other components in the braking system.

One of the key features of these brake discs is the multilayer anti - rust coating technology. This technology significantly enhances the corrosion resistance and service life of the brake discs. In a salt - spray test, the brake discs with this coating can resist corrosion for up to 500 hours, far exceeding the industry average. This means that even in harsh environments such as coastal areas or areas with heavy snow and salt on the roads, the brake discs can maintain their performance and appearance for a long time.

The brake discs hold several international quality certifications, including IATF TS16949, R90 E - mark, and VCA COP. The IATF TS16949 certification indicates that the company has a strict quality management system in place, ensuring that every brake disc meets high - quality standards from raw material procurement to final product delivery. The R90 E - mark is a European certification that guarantees the safety and performance of the brake discs. The VCA COP certification further validates the quality and compliance of the brake discs in the UK market.

| Certification | Significance |

|---|---|

| IATF TS16949 | Strict quality management system |

| R90 E - mark | European safety and performance guarantee |

| VCA COP | UK market compliance |

When selecting brake discs, several factors need to be considered. First, check the vehicle model. These brake discs are compatible with 99% of vehicle models, but it's still necessary to confirm the specific model code. Second, consider the driving environment. If you often drive in mountainous areas or heavy - traffic cities, you may need brake discs with better heat dissipation and wear resistance. Third, look at the certification. The international certifications mentioned above are a guarantee of quality.

For commercial vehicles, upgrading the brake system can significantly improve safety and efficiency. These high - performance brake discs are an ideal choice for such upgrades. They can reduce the braking distance by up to 10% compared to ordinary brake discs, which is crucial for large - scale commercial vehicles.

To ensure the long - term performance of the brake discs, regular maintenance is necessary. Check the brake discs every 10,000 - 15,000 kilometers for wear and tear. Clean the brake discs regularly to remove dust and debris. If you notice abnormal noises or vibrations during braking, have the brake discs inspected immediately.

In conclusion, Laizhou Guanzhao Trading Co., Ltd.'s high - performance, wear - resistant, and rust - proof brake discs offer a comprehensive solution for vehicle braking needs. With superior materials, advanced technology, and international certifications, they are a reliable choice for both individual vehicle owners and commercial vehicle fleets. If you want to ensure your vehicle's braking safety and performance, click here to consult our customized solutions and download the technical whitepaper.

.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)