When it comes to the safety of commercial vehicles, the braking system is undoubtedly the most critical component. Among them, the correct installation of brake discs is a key factor in ensuring the stable operation of the braking system. However, many front - line maintenance personnel and fleet managers often fall into some common installation pitfalls, which can lead to various problems such as abnormal noises, vibrations, and even brake failures.

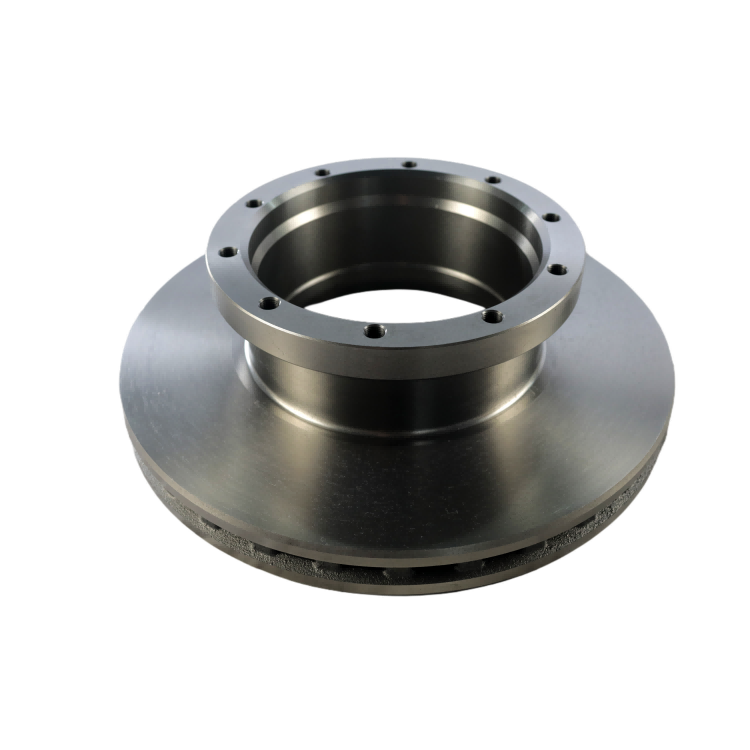

In this article, we will focus on the importance of positioning hole accuracy, turning, and grinding processes in the installation of commercial vehicle brake discs. Let's first understand the significance of positioning hole accuracy. The positioning hole of the brake disc is like the "anchor" of the entire braking system. If the accuracy of the positioning hole does not meet the standard, it will directly affect the alignment of the brake disc on the hub, resulting in uneven stress during braking.

According to relevant data, in 70% of brake - related accident cases, improper installation of brake discs due to inaccurate positioning holes was one of the important reasons. Therefore, ensuring the accuracy of positioning holes is crucial for the safety of the braking system. In addition to positioning hole accuracy, turning and grinding processes also play a vital role in the quality of brake discs. Turning and grinding can effectively ensure the flatness of the disc surface and the consistency of thickness. A brake disc with a flat surface and consistent thickness can ensure that the brake pads come into full and uniform contact with the disc surface during braking, thereby improving braking efficiency and stability.

Let's take a look at how to ensure the flatness of the disc surface and the consistency of thickness through turning and grinding processes. During the turning process, the cutting tool precisely removes the excess material on the disc surface, making the surface smoother. The grinding process further refines the surface finish of the brake disc, reducing friction coefficients and improving braking performance. As shown in Figure 2, through scientific turning and grinding processes, the surface roughness of the brake disc can be controlled within 0.8 - 1.6 microns, which is a key indicator for ensuring stable braking.

Now, let's talk about the specific installation steps. First, before installation, carefully clean the hub and the mating surface of the brake disc to remove any dirt, rust, or debris. Then, use a high - precision measuring tool to check the accuracy of the positioning holes of the brake disc. During installation, use the recommended tools, such as torque wrenches, to ensure that the bolts are tightened to the specified torque. Here is a simple installation step table for your reference:

| Step | Operation |

|---|---|

| 1 | Clean the hub and brake disc mating surface |

| 2 | Check the accuracy of positioning holes |

| 3 | Install the brake disc on the hub |

| 4 | Tighten the bolts with a torque wrench to the specified torque |

Let's look at a real - life case. A logistics company once had a high incidence of brake - related problems in its fleet. After inspection, it was found that the inaccurate installation of brake discs was the main cause. After adopting the correct installation method and using high - quality brake discs, the incidence of brake problems in the fleet decreased by 80% within a year, greatly improving the safety and operational efficiency of the vehicles.

To ensure the safety of your vehicles' braking systems, we highly recommend the high - quality commercial vehicle brake discs from Laizhou Guanzuo Trading Co., Ltd. Their brake discs feature high - precision positioning holes and excellent machining advantages, which can effectively guarantee the safety of your braking system. Don't let improper installation put your vehicles and drivers at risk. Click here to learn more about these reliable brake discs and take the first step towards safer driving!

We encourage you to leave your comments below. Share your experiences in brake disc installation and let's learn from each other to improve the safety of commercial vehicle braking systems.

.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)