Brake disc installation is a critical process that, when done incorrectly, can lead to a range of issues such as abnormal noises, vibrations, and even brake failure. In real - world scenarios, there are several typical mistakes. For instance, misaligned positioning holes are a common problem. When the positioning holes on the brake disc do not match precisely with the corresponding parts on the vehicle, it can cause uneven stress distribution during braking. Another common error is rough installation, where mechanics may use excessive force or improper tools, which can damage the brake disc surface and internal structure. According to industry statistics, approximately 30% of brake - related problems in commercial vehicles are caused by incorrect installation.

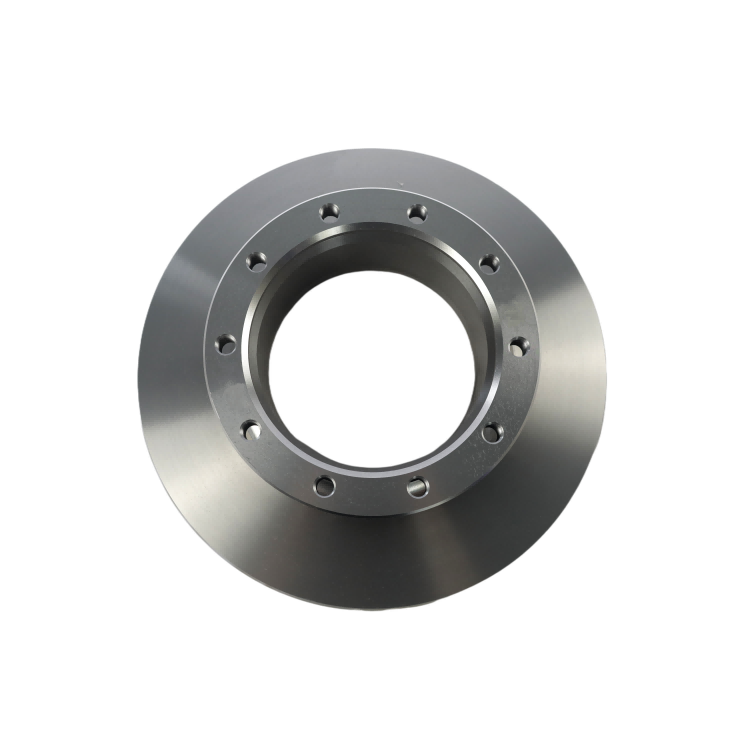

Turning and grinding processes play a crucial role in achieving high - precision control of the brake disc surface. Turning is a process that uses a cutting tool to remove material from the rotating brake disc, which can effectively control the thickness and shape of the disc. Grinding, on the other hand, is used to further refine the surface finish, ensuring the flatness and smoothness of the brake disc. By combining these two processes, manufacturers can achieve a high degree of thickness consistency and dynamic balance. For example, through advanced turning and grinding techniques, the thickness variation of a brake disc can be controlled within ±0.05mm, which significantly improves the braking performance and stability.

A standardized installation process is essential for ensuring the proper functioning of brake discs. First, the right tools must be selected. For example, a torque wrench is necessary to ensure that the bolts are tightened to the correct torque. Second, thorough cleaning is required. Any dirt, debris, or rust on the brake disc and the mounting surface can affect the installation quality. Third, the correct tightening torque is crucial. Over - tightening or under - tightening the bolts can lead to uneven stress on the brake disc, causing premature wear or failure. The following is a step - by - step guide:

There are numerous real - world cases that demonstrate the negative impacts of incorrect brake disc installation. A fleet management company once reported that due to improper installation of brake discs, the failure rate of their vehicles' braking systems increased by 25% within a year. This led to a significant increase in maintenance costs, including the replacement of damaged brake discs and other related parts. In addition, the downtime of the vehicles also caused economic losses due to missed delivery schedules. Another case involved a repair shop where several customers complained about brake noises and vibrations shortly after the brake disc replacement. After investigation, it was found that the installation errors were the root cause.

In the context of the IATF TS16949 certification, which is a globally recognized quality management system for the automotive industry, the importance of quality control in brake disc manufacturing and installation cannot be overstated. This certification emphasizes strict quality management from raw material procurement to the final product delivery. Manufacturers that comply with this standard are more likely to produce high - quality brake discs with precise positioning holes and excellent machining quality. As the industry evolves, more and more companies are focusing on improving the quality and reliability of their brake systems to meet the increasing safety requirements.

Do you ever encounter brake noises or vibrations in your commercial vehicles? If so, it may be due to incorrect brake disc installation. By choosing our brake discs with precisely designed positioning holes and high - precision machining, you can ensure a safer and more reliable braking experience. Choose our brake discs with positioning hole design and make every brake application safe and reliable!