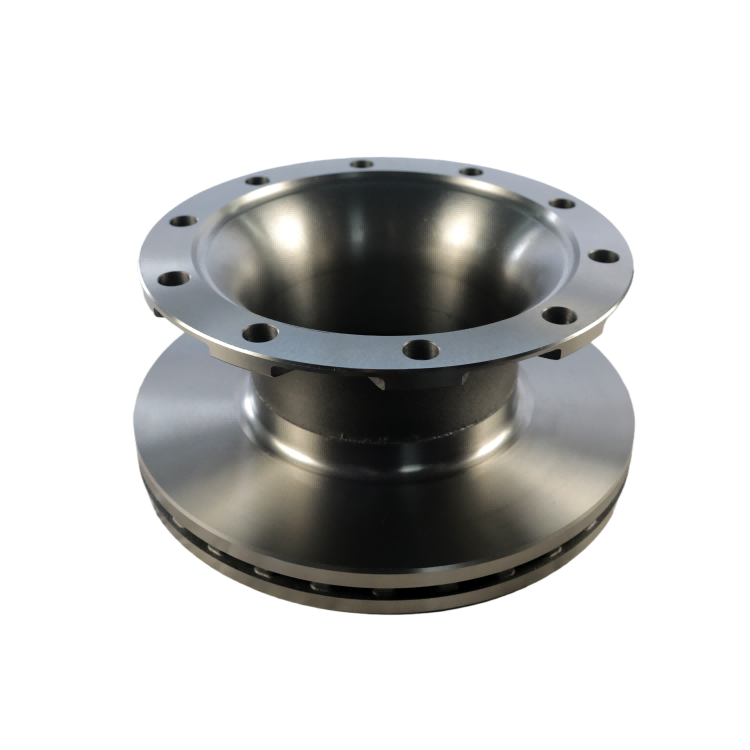

Reliable braking systems are the backbone of commercial vehicle safety. Among the numerous factors influencing brake efficiency, the precision machining of brake discs stands as a decisive determinant. This article rigorously investigates the impact of machining quality—especially the dimensional accuracy of positioning holes and turning and grinding processes—on the overall performance and safety of commercial vehicle brake discs.

Brake discs, also known as brake rotors, must guarantee uniform thickness and surface flatness to maintain optimal braking stability. In commercial vehicles, these parameters become even more critical due to heavier loads and frequent stop-start cycles. Industry studies indicate that up to 35% of premature brake failures in commercial fleets can be traced to improper machining and assembly inconsistencies.

Among common pitfalls, inaccuracies in positioning hole diameters and eccentricities lead to uneven mounting, causing vibrations and brake judder. Furthermore, inconsistent turning (lathe) and grinding operations contribute to surface irregularities that adversely affect friction and generate abnormal noises.

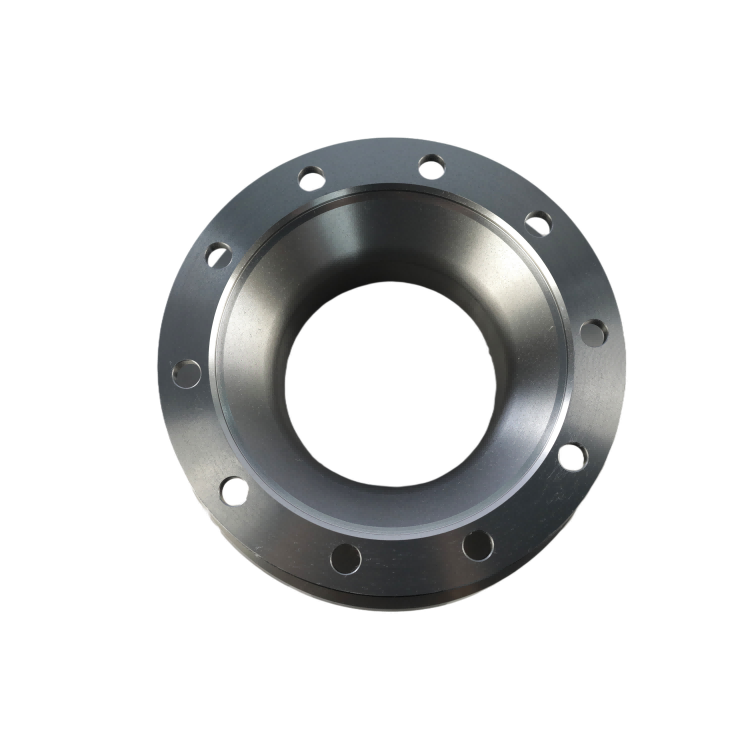

The correct sizing and concentricity of positioning holes are non-negotiable. Tolerances as tight as ±0.02 mm must be maintained to ensure the brake disc mounts flush without lateral runout. Deviations beyond these limits have been shown to increase disc vibration frequency by up to 20%, directly impacting braking comfort and component life.

Turning and grinding processes are equally vital. High-quality lathe cutting preserves the disc’s flatness, with surface roughness (Ra) levels ideally below 1.6 µm, creating an optimal interface for brake pads. Subsequent precision grinding guarantees uniform disc thickness, typically within a 0.03 mm variance tolerance, minimizing thermal distortion and uneven wear.

Misapplication during brake disc installation remains a serious challenge in fleet maintenance. Key errors documented include incorrect torque application on mounting bolts, failure to clean mating surfaces, and neglecting to use proper installation tools.

These lapses result in warping and misalignment, which manifest as persistent brake squeal, pedal pulsation, and in severe cases, brake fade or failure. A recent field study found that 45% of service calls related to brake system complaints stemmed from avoidable installation mistakes.

Implementing a standardized installation protocol significantly reduces the risk of assembly errors. Industry best practices advocate the following sequence:

Using specialized tools such as digital measuring microscopes and precision torque calibrators has been shown to improve first-time-right installation rates by over 30%, directly enhancing fleet reliability.

Consider a logistics fleet implementing upgraded machining standards, focusing on positioning hole accuracy and refined turning/grinding protocols. Over a six-month monitoring period, they reported:

This comprehensive exploration underlines the necessity for frontline maintenance technicians and fleet managers to adopt precise machining quality standards and standardized installation protocols. Regular training paired with clear documentation strengthens operational consistency and road safety.

Moreover, leveraging these insights through official channels and multi-platform dissemination can amplify brand authority and build lasting customer trust within the commercial vehicle sector.

Discover Our Precision-Engineered Brake Discs & Enhance Your Fleet’s Safety Today