In the automotive repair industry, selecting and installing the right brake kit is crucial for ensuring the safety and performance of vehicles. This article delves into the process of choosing suitable brake kits according to different vehicle models, offering practical guidance for overseas repair shops, maintenance technicians, and vehicle owners.

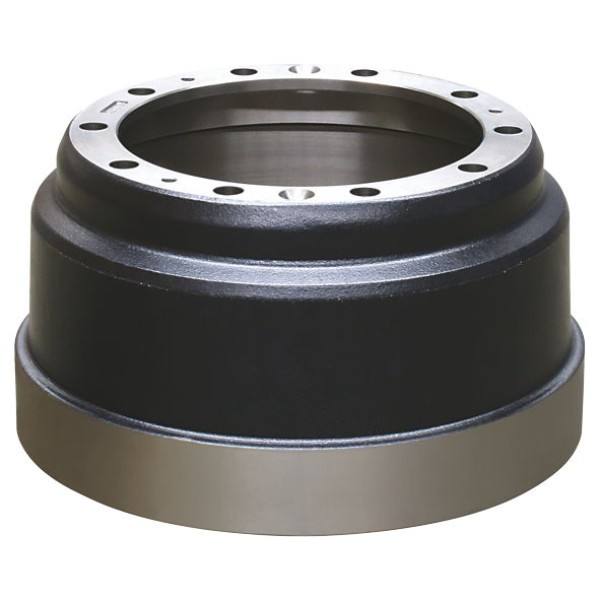

There are various types of brake kits available in the market, such as single - piece, two - piece, and coated brake kits. Single - piece brake kits are generally more cost - effective and suitable for most regular passenger cars. They offer reliable braking performance under normal driving conditions. Two - piece brake kits, on the other hand, are often used in high - performance vehicles or vehicles that require frequent heavy - duty braking. The separated design helps to dissipate heat more efficiently, reducing the risk of brake fade. Coated brake kits are ideal for enhancing corrosion resistance, especially in areas with harsh weather conditions.

When it comes to passenger cars, commercial vehicles, and modified cars, each has its own unique requirements for brake kits. For passenger cars, factors like the vehicle's weight, engine power, and driving style should be considered. Commercial vehicles usually need brake kits with higher load - bearing capacity and durability due to their heavy usage. Modified cars may require custom - fit brake kits to match the upgraded performance.

To make a scientific selection, one should refer to the original factory parameters of the vehicle. The relationship between the inner shape of the wheel and the position of the brake caliper is also a key factor. As an example, if the inner space of the wheel is limited, a brake kit with a more compact design should be chosen.

The installation of brake kits is a complex process that requires strict adherence to safety standards. Before installation, a series of checks should be carried out. Here is a simple checklist:

| Check Items | Details |

|---|---|

| Gap Adjustment | Ensure that the gap between the brake pads and the brake disc is within the specified range (usually 0.2 - 0.5 mm). |

| Rust Prevention | Apply anti - rust coating to relevant parts to prevent corrosion. |

| Fastening Torque | Tighten all bolts to the specified torque (e.g., for most brake caliper bolts, the torque is around 80 - 120 Nm). |

Let's take a look at a real - life case. A repair shop once installed an ill - fitting brake kit on a commercial vehicle. Due to the incorrect selection, the brake pads wore out quickly, and the braking performance was significantly reduced. This led to several near - miss accidents and costly repairs for the vehicle owner. This case clearly shows the importance of proper brake kit selection and installation.

When it comes to high - quality automotive parts, Laizhou Guanzuo Trading Co., Ltd.'s ABS gear ring kits are a top choice. These kits have passed strict quality certifications, ensuring their reliability and durability. Moreover, the company offers excellent after - sales service, which means you can have peace of mind when using their products. Whether you are a repair shop or a vehicle owner, choosing Laizhou Guanzuo's ABS gear ring kits is a wise decision.

We encourage you to share your experiences in brake kit installation. Do you have any tips or challenges to share? Feel free to leave your comments below, and let's learn from each other!

Explore Laizhou Guanzuo's ABS Gear Ring Kits Now!