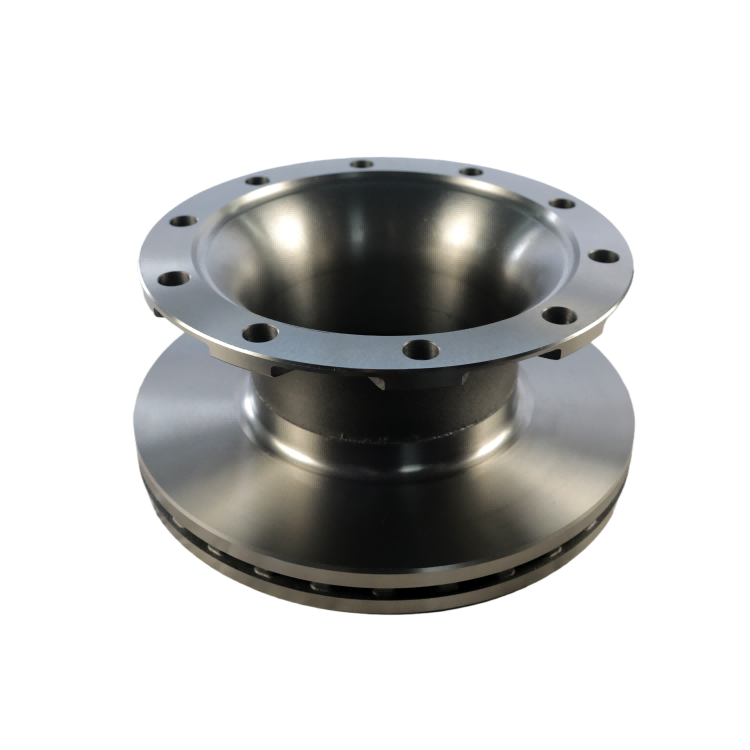

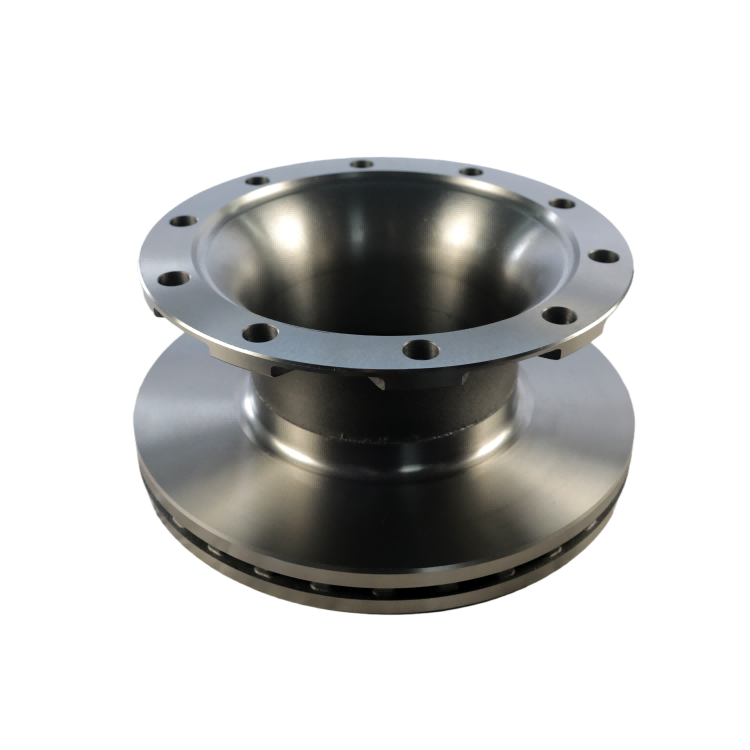

Precision Positioning Holes and Advanced Turning Processes for Brake Discs to Enhance Vehicle Braking Performance

Laizhou Guanzhuo Trading Co., Ltd.

2025-12-27

Solution

Frequent brake disc installation errors often compromise vehicle safety. This article explores how precise positioning holes and high-quality turning processes are essential for preventing brake noise, vibration, and failure. By analyzing common mistakes made by frontline technicians, it highlights the impact of inaccurate hole alignment and rough machining on braking stability. Through case studies with detailed comparisons, we explain how turning and grinding techniques ensure flatness and consistent thickness of the disc surface, ultimately improving braking performance. Recommended: Laizhou Guanfu commercial vehicle brake discs—with international certifications, 99% vehicle compatibility, and a 2-year warranty—offering reliable and worry-free braking every time.

Avoiding Common Mistakes: Precision in Brake Disc Installation

When it comes to commercial vehicle brake discs, accuracy isn’t optional—it’s critical. A frequent source of braking issues is improper installation, particularly errors related to the positioning holes and disc surface calibration. You might have seen symptoms such as unusual noises, steering wheel vibrations, or even compromised braking effectiveness. These often trace back to installation mistakes like misaligned positioning holes or inconsistent rotor surfaces. Understanding these errors is your first step to safer, smoother braking.

Common Installation Errors and Their Impact

- Positioning Hole Misalignment: Causes uneven mounting leading to rotor runout and brake pulsation.

- Skipping Surface Calibration: Results in inconsistent rotor thickness causing brake judder and premature wear.

- Improper Fastening Sequence: Generates uneven pressure distribution, increasing the risk of warping.

Ignoring these can escalate from minor inconveniences to serious safety hazards on the road.

Why Precision Positioning Holes and Advanced Machining Matter

The brake disc’s positioning hole tolerances affect how perfectly the disc aligns with the hub. Precision within ±0.02 mm is standard for top-tier commercial brake discs. Such exactness prevents lateral runout that causes vibrations and uneven pad wear. Complementing this, sophisticated turning and grinding processes ensure that the disc surface maintains strict flatness and thickness variation under 0.01 mm. This level of craftsmanship guarantees that every braking force is distributed evenly and predictably.

Expert Insight: "Consistent rotor geometry arising from precision machining directly correlates to improved braking performance and longer component life. Neglecting these factors is a frequent cause of in-service failures." — Automotive Brake Specialist

Standardized Installation Process for Maximized Safety

- Clean the hub and rotor seating surfaces thoroughly.

- Align the rotor using precision positioning holes; verify alignment with dial gauges.

- Use a calibrated torque wrench to tighten bolts in a crisscross pattern to manufacturer’s specs.

- Inspect the rotor surface for flatness and thickness uniformity before and after installation.

- Test brake function under controlled conditions, checking for noises, vibrations, or warning signals.

Always follow your vehicle’s service manual, use recommended tools, and adhere to safety protocols throughout.

Real-World Comparisons: What Proper Machining Looks Like

In one field case, a fleet experienced persistent brake pulsation traced to worn rotors with inconsistent thickness over 0.05 mm. After switching to discs featuring precise positioning holes and turning tolerance under 0.01 mm thickness variation, vibration complaints dropped by over 90%. Visual microscopy confirmed smoother, more uniform disc surfaces consistent with high-quality machining standards.

Choosing the Right Brake Disc: The Laizhou Guanzhen Advantage

Laizhou Guanzhen’s commercial brake discs combine cutting-edge turning and grinding techniques with precision-engineered positioning holes that meet international certifications. Designed for compatibility across 99% of commercial vehicle models, each disc comes backed by a dependable two-year warranty, ensuring peace of mind with every braking event.

Guarantee your vehicle’s braking safety with a proven solution that prevents installation errors and maximizes performance.

Questions? Leave your thoughts below and our experts will assist you.