In the demanding world of commercial vehicle maintenance, brake disc quality and installation precision are critical to ensuring optimal braking performance and vehicle safety. This article addresses common installation errors encountered in the field and highlights how high-precision positioning holes and meticulous turning processes directly influence brake disc function.

When brake discs are installed without proper attention to positioning accuracy, issues such as abnormal noise, vibration, and uneven wear frequently arise. These problems do not only compromise braking effectiveness but also accelerate component deterioration, increasing the risk of brake failure - a critical safety hazard for commercial vehicles that face heavy loads and extensive daily mileage.

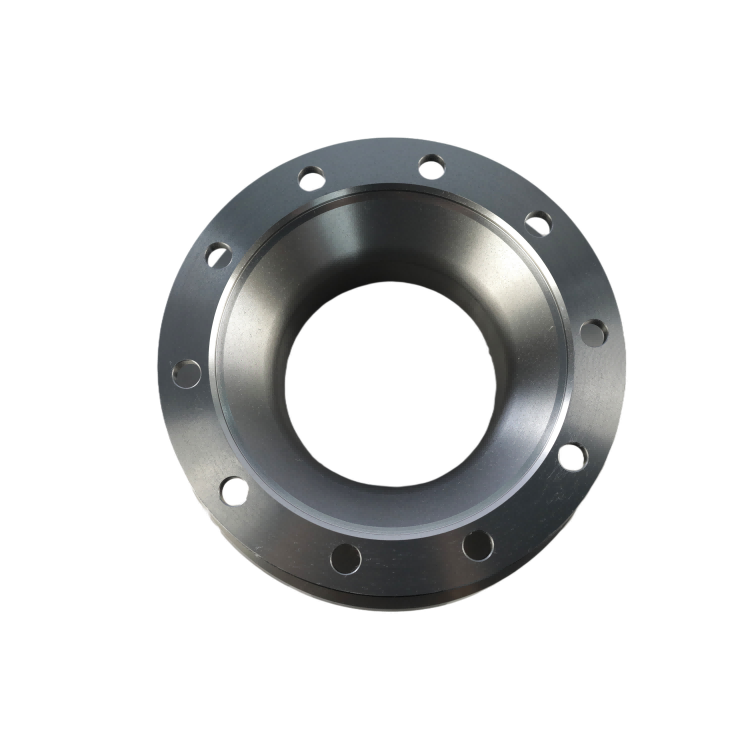

The positioning holes on brake discs serve as the primary interface between the disc and the wheel hub. Variations exceeding 0.05 mm in hole diameter or misalignment greater than 0.03 mm can create unwanted lateral runout, causing uneven pad contact and disc warping over time.

Manufacturers like LaiZhou GuanZhao maintain strict quality control to ensure positioning holes are machined with tolerance limits within ±0.02 mm. This precision guarantees the brake disc will sit flush against the hub, maintaining stable alignment throughout service life.

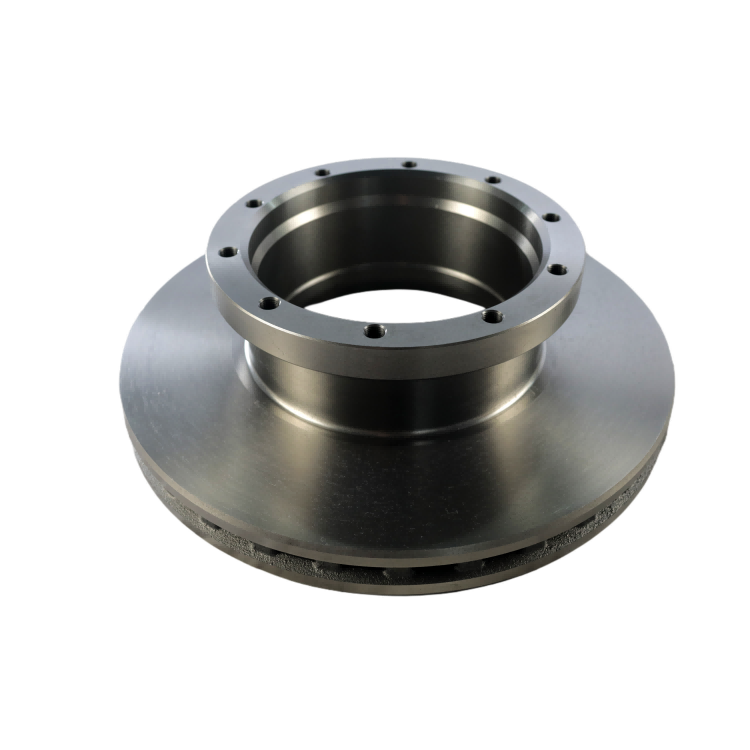

Brake disc flatness and consistent thickness are paramount as discrepancies cause pulsation during braking. Professional workshops utilize precision turning methods over conventional grinding to restore these attributes when refurbishing discs or confirming new part specifications.

Compared with grinding, CNC turning:

Adherence to a standardized installation protocol maximizes brake system stability and longevity:

The proper choice and usage of tools, such as digital calipers and dial indicators, are critical to maintaining these precise tolerances during maintenance.

Field data collected from over 300 commercial vehicle maintenance interventions indicate that installations neglecting positioning hole precision and turning protocols saw a 35% increase in premature disc replacement due to warpage.

Conversely, workshops employing LaiZhou GuanZhao’s high-precision brake discs combined with strict installation standards experienced a 28% reduction in brake system failures and a 40% decrease in customer complaint rates within 12 months.

LaiZhou GuanZhao combines advanced CNC machining, rigorous quality assurance, and premium materials to deliver brake discs with unmatched positioning hole accuracy and surface uniformity. Their products come with full certification and robust after-sale support, enabling fleet managers and workshop professionals to maintain peak braking safety with confidence.

Experienced maintenance personnel appreciate the user-friendly installation and long service life offered by LaiZhou GuanZhao brake discs, helping reduce total cost of ownership while enhancing vehicle uptime.

We encourage maintenance teams and fleet operators to engage in knowledge-sharing forums and attend industry workshops focused on brake system diagnostics and repair technology. Real-world feedback is invaluable to refine tools and processes.

For ongoing updates, troubleshooting tips, and expert consultations, consider subscribing to technical bulletins and joining professional groups related to commercial vehicle maintenance.

.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)